This system was designed to feed 2 sizes of magnets being assembled into an automotive product. A step feeder was chosen for space savings and durability. This system features a step feeder bin, proximity sensors, and a pre-feeder conveyor belt.

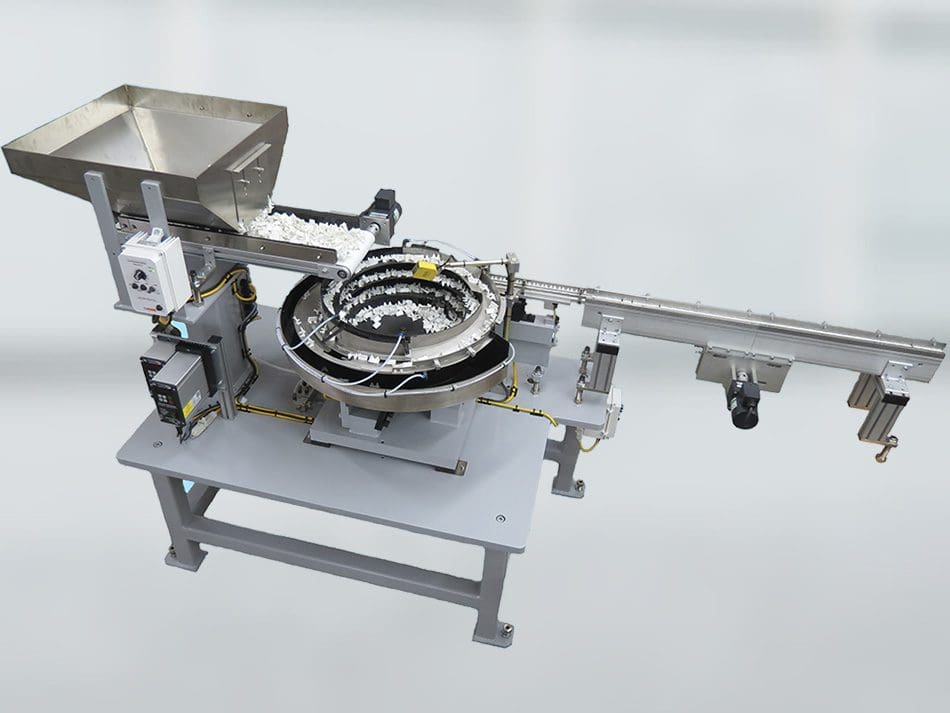

Centrifugal Feeder Feeds 1300 Pharmaceutical Parts per Minute

This system was designed for a pharmaceutical product manufacturer who needed to orient and feed two types of round plastic parts at a rate of 1300 parts per minute. We used a centrifugal bowl feeder for this project because of the high feed rate requirement.

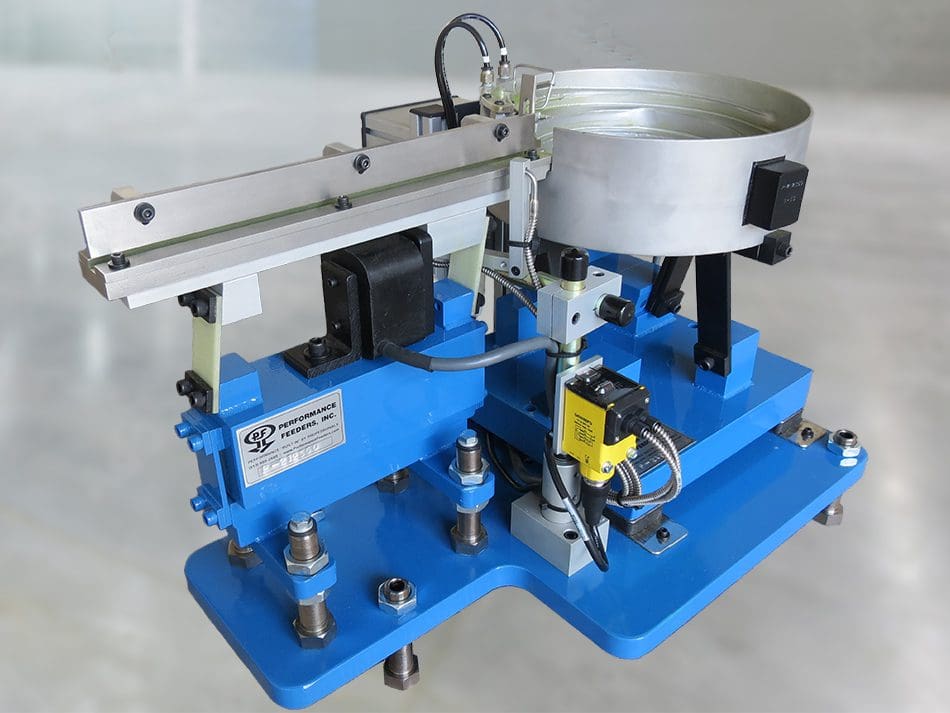

Vibratory Floating Mandrel Feed System Feeds Thin Metallic Washers

This system was designed for a consumer products manufacturer to feed two types of washers: A wavy spring washer and a fiber washer. Vibratory bowl feeders were used to orient both parts, and the feed systems were mounted on a common table to save space and cost.

Medical Packaging Belt Conveyor System

This conveyor belt system was designed for a medical device manufacturer who needed to package a medical product into boxes. This conveyor had a low-friction belt to allow the loaded boxes to be pushed across the belt perpendicular to the conveyor’s direction of travel.

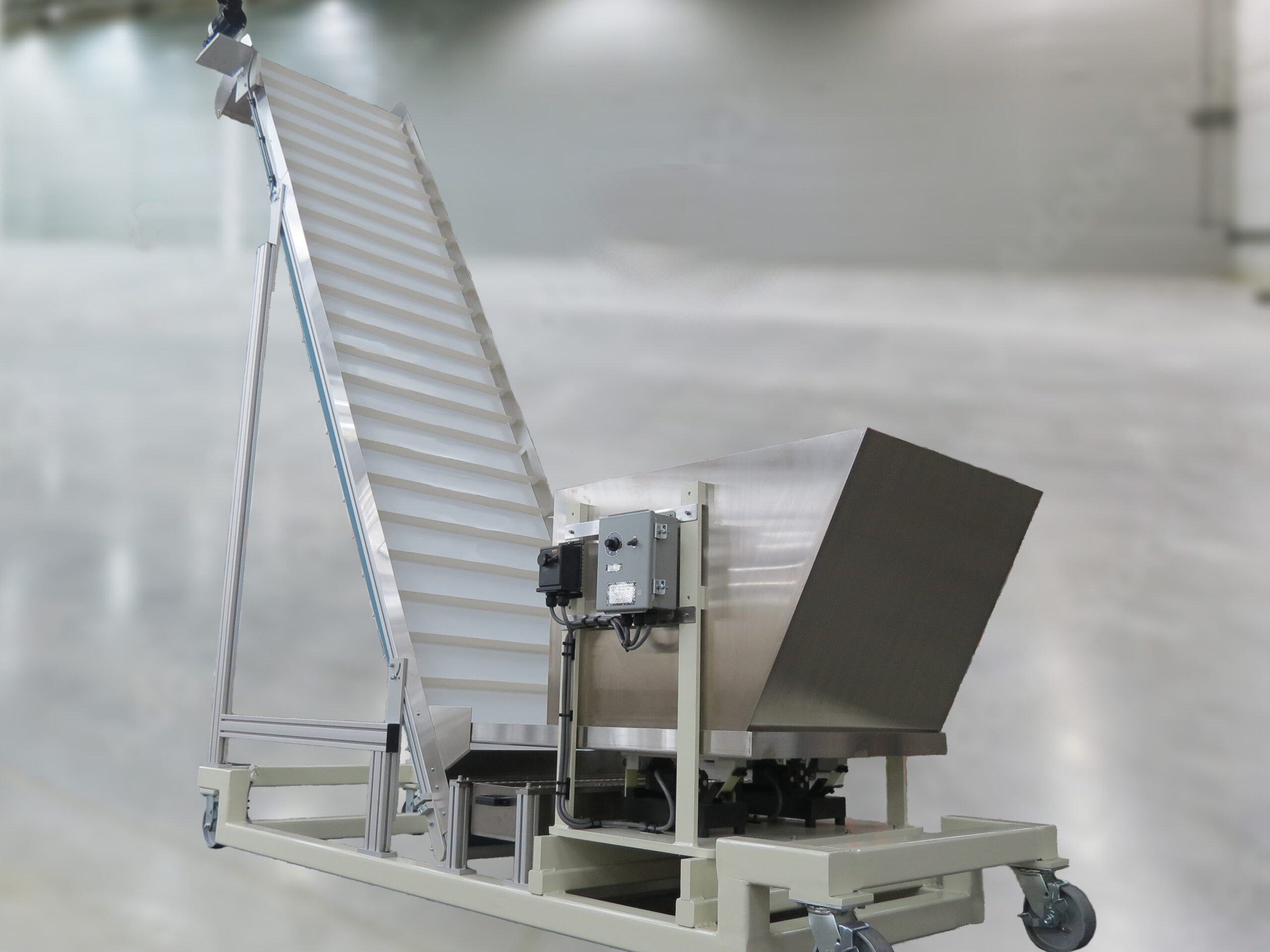

Elevator Belt Conveyor System with Storage Hopper for Food Packaging

This system was designed for a food manufacturer who needed to move a whole-grain snack product to a packaging operation, which required the product to be delivered 10′ off the floor. The manufacturer needed bulk product storage at floor level and a way to remove as much small and broken pieces of product as possible before moving into the packaging operation.

Vibratory Feeder for Medical and Pharmaceutical Applications

This vibratory bowl feeder system was designed to orient and feed 7 different types of plastic bottles into a pharmaceutical filling and packaging system. The bowl was built with FDA-grade 316 stainless steel. To ensure that all bowl surfaces were smooth, pit-free and resistant to dust collection.

Vibratory Feeder Bowl Reliably Feeds O-Rings

Feeding o-rings in vibratory bowl systems has been historically problematic due to buildup of static electricity causing the parts to stick together and stick to the bowl surface. We solved this problem by integrating an ionizer into a vibratory parts feeding system.

Hybrid Vibratory Feeder – Conveyor System for Gentle Parts Handling

A component of a sensor for a consumer product was made of a plastic material that was susceptible to damage from vibration. The assembly operation also required that the parts be kept as clean as possible. We designed a custom parts feeding system that combined a vibratory feeder bowl and straight line track with belt conveyors to provide an effective solution to these unique design challenges.

Ultra-Compact Vibratory Bowl Feeder Orients Small Rubber Parts

This vibratory bowl feeder was designed to feed an automotive part. With a low feed rate and tight space requirements, we designed a parts feeding system that allowed our customer to pick the part up directly from the bowl.

Vibratory Feeder Bowl System with Center Discharge

This vibratory parts feeding system was designed to feed two sizes of a part used in air conditioner desiccant systems. The simple cylindrical shape of the parts allowed the use of a “cascade” type bowl feeder, where all part orientation is performed within the inside diameter of the bowl. This eliminated tooling construction on the outside of the bowl, which along with the right-angle discharge into the vibratory track, resulted in a compact vibratory feed system that met our customer’s space requirements.