Flex Feeders

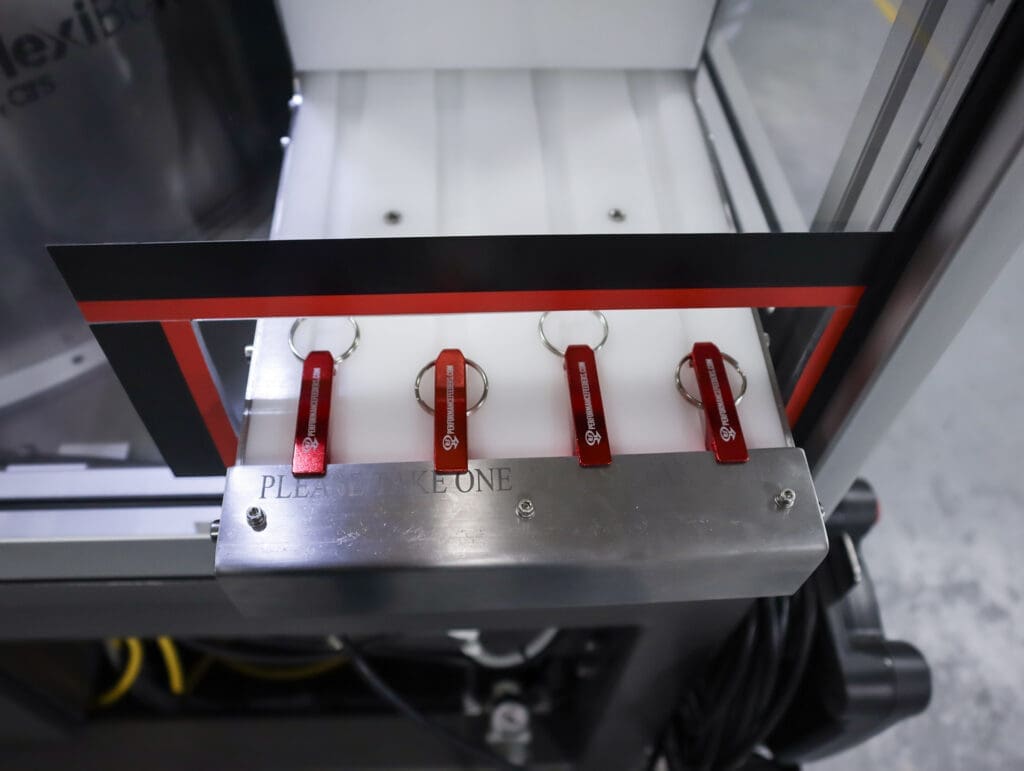

Performance Feeders’ flexible parts feeding solutions are designed for optical inspection and robotic part selection with a backlit belt conveyor, recirculating turntable, or simplified standard feeding systems. They offer a variety of solutions for complex part geometries, small parts and families of parts that are not easily fed in conventional feeder systems. From the simple, economy conveyor matrix to the Flexi-bowl turntable model, numerous upgrades are available to provide as little or as much customization as required up to a complete turnkey solution with robot and vision system integration.

Flexible Feeding Solutions

The Flexible parts-feeding systems offer a variety of solutions for complex part geometries, small parts and families of parts that are not easily fed in conventional feeder systems.

Features

- Multiple part capabilities: Because of the simple method of product presentation associated with flex feeding and the heavy reliability on advanced technologies, changing from one part to another can be extremely quick and simple once initially programmed.

- Gentle Part handling: Due to the recirculating nature of the systems, minimal dispersion tooling is required allowing product to disperse naturally with minimal tooling contact.

- Elevating Storage Bin: The stainless steel elevating storage bin allows for the storage of 3 cu ft of un-oriented parts. The key features of this elevator are the low load height and quick dump door which allows for ease of use and assists with quick product changeover.

- Return Conveyor: Product return conveyors drive product back to the elevating storage bin for recirculation as required.

Feed Rates: 45+ parts per minute can be achieved depending upon product characteristics and ancillary equipment used.

Multiple Point Placement can be programmed to fill multiple lanes of product, limited only by robot reach.

Additional Features & Specification

- SCARA robot and 6 axis robotic integration with PLC, HMI, and VFD’s

- Standard unit is 240 VAC Single Phase 60 hz power requirements

- Vision guided tracking and product analysis

- Part specific bulk supply hoppers and feeding solution

- Heavy duty base frame and safety cage

- Capable of orienting a single line of random product

- Able to create multiple lanes of product from a single lane.

Versatile FlexiBowl Feeder

FlexiBowl Features:

- Multiple Flex Feeding options

- Ability to feed multiple parts at the same time in one system

- Handles a wide variety of part materials, shapes and sizes

- Easily reconfigured to accommodate part changes

- User-friendly software

- Clean-room applications