This vibratory feed system includes a laser inspection station, a bowl level sensor, a track sensor, and a sorting indexer. Parts with an incorrect length are rejected while the correct parts are oriented threads-up in groups of 4.

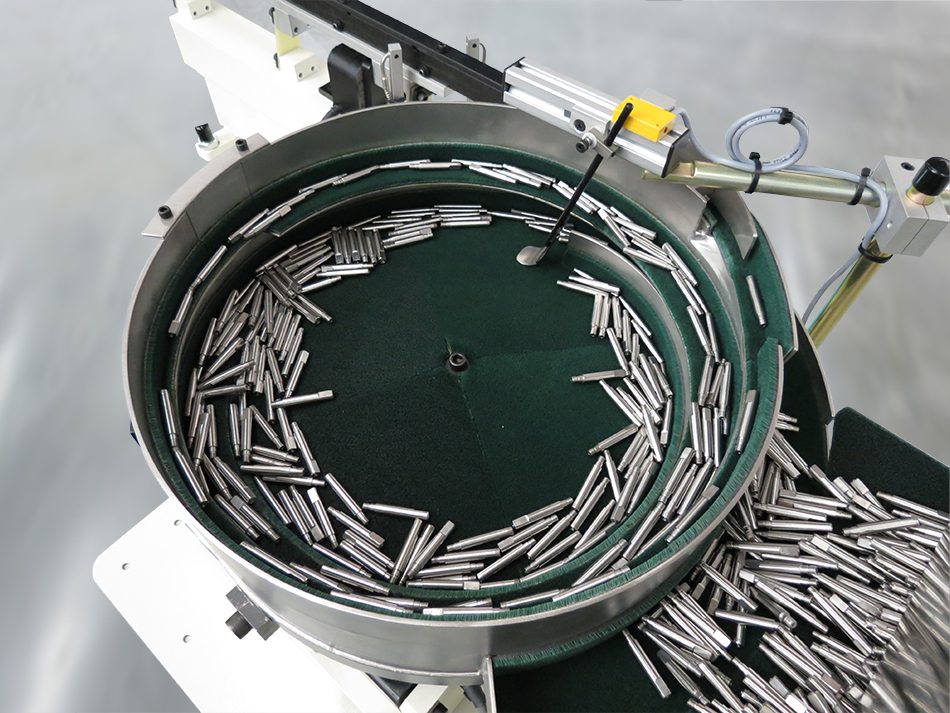

Vibratory Feeder with Gentle Parts Handling Features Minimizes Damage

This Brushlon-lined vibratory bowl feeding system was designed to feed two lengths of a polished steel shaft being assembled into a consumer product. Maintaining the cosmetic integrity of the parts was of utmost importance, so we designed a vibratory feed system that minimized the possibility of damage to the parts.

Turn-Key Vibratory Feeder With Bad Part Reject Feeds 2 Part Types into Assembly Line.

This vibratory feeder with custom conveyor belt tracking was designed to feed 2 styles of plastic parts into a consumer appliance assembly operation. The application required 4 lines of parts (2 lines of a left-hand version and 2 lines of a right-hand version), with each line alternating between the left-hand and right-hand part version. Each bowl feeder had to allow for the possibility of the wrong part being in the system, and an isolation mechanism was required so that 2 parts could be picked up from each line simultaneously.

Vibratory Feeder With Integrated Optical Inspection System Orients Parts Based On Internal Features

This vibratory feed system was designed to feed a metal washer into a machine assembling a consumer product. While flat, round parts like washers are normally easy to feed, this part had a small indentation on one side that needed to be oriented facing down. A Vision System checked the part for correct orientation before discharging it onto a straight-line track and into the customer’s assembly station.

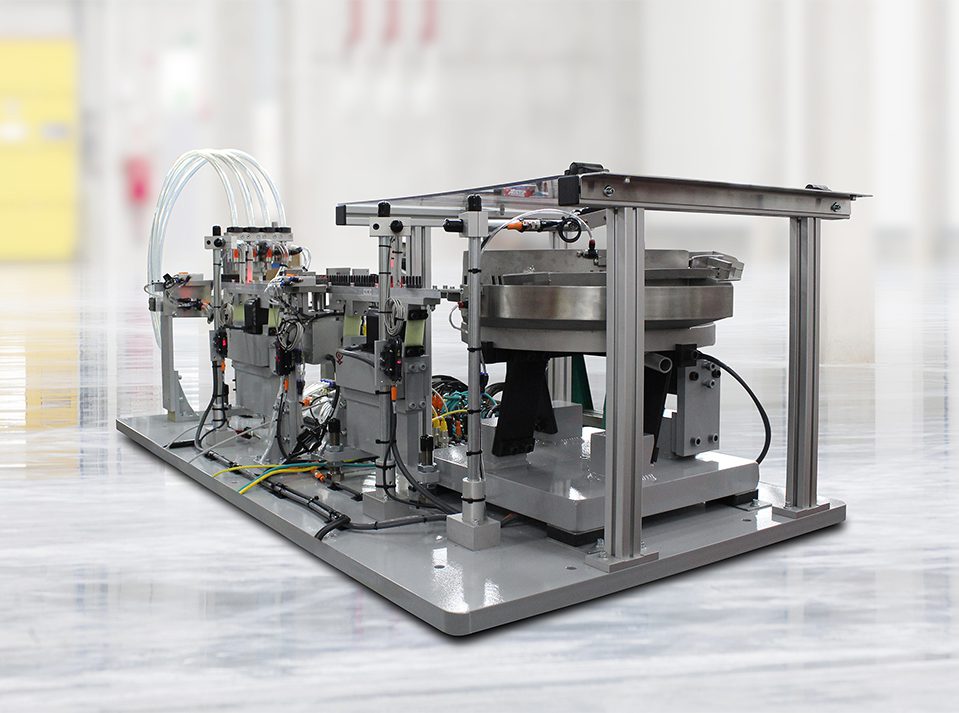

Vibratory Floating Mandrel Feed System Feeds Thin Metallic Washers

This system was designed for a consumer products manufacturer to feed two types of washers: A wavy spring washer and a fiber washer. Vibratory bowl feeders were used to orient both parts, and the feed systems were mounted on a common table to save space and cost.

Conveyor Belt System with Automatic Tray Loading

This Custom Conveyor System was designed for a manufacturer who needed to load empty trays with parts for an automatic assembly operation. Empty trays were loaded onto a powered Auto-Kinetics heavy-duty belt conveyor. Upon reaching the end of the belt conveyor, a pneumatic slide pushed a single tray sideways onto a robotic loading station. Once in position, a second pneumatic slide clamped the tray in place for loading.