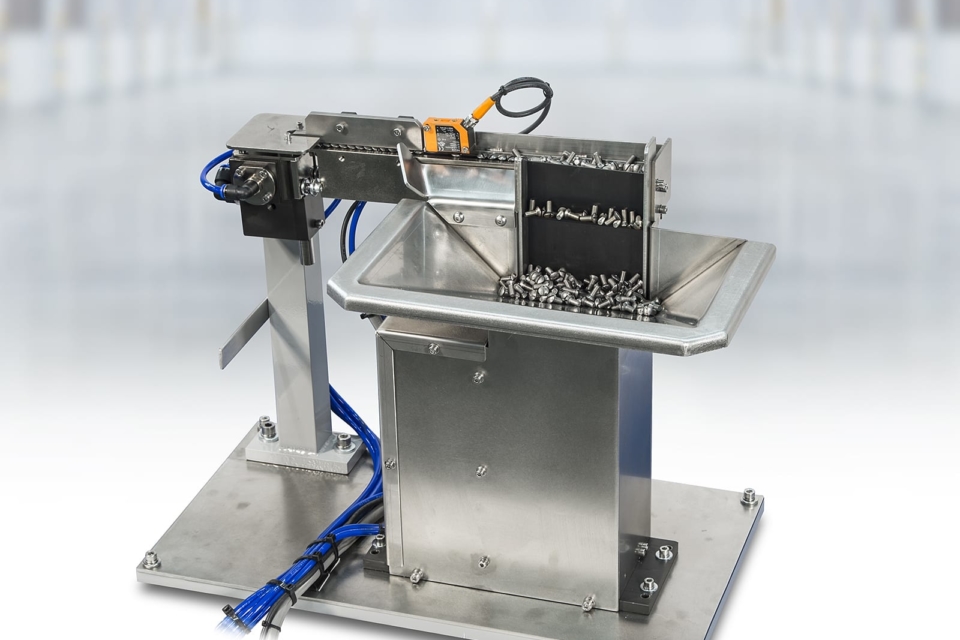

Step Feeders

Performance Feeder’s step feeders are capable of feeding small cylindrical and spherical parts. They offer numerous advantages over conventional feeding methods, including quiet operation, space savings, and gentle handling of parts. Our step feeders are available in several configurations ranging from standalone units to completely tooled feed systems.

How They Work

Bulk parts are lifted out of the integrated hopper bin by the step. The step thickness is selected so that a single row of parts is lifted. At the top of the step stroke, the parts drop onto a linear feeder (vibratory inline, belt conveyor or air track), where additional orientation can be performed. Improperly oriented parts that are ejected from the orienting track can often drop directly back into the bin, or can be returned to the bin via gravity slide, air track or conveyor in situations where more complex orientation is performed on the orienting track.

BROWSE OUR COMPLETE LINE OF STEP FEEDING PRODUCTS

Features

- Vertical Step Configuration: Our vertical step design results in a reduced footprint, saving space, and increases efficiency by reducing the resistance caused by the step pushing through a bin full of parts.

- Simple, Air-Powered Operation: The step feeders are powered by a single air cylinder and operate with a 32 PSI air supply.

- Integrated Hopper Bin: The stainless steel bin provides for storage of up to 1/2 cu. ft. of unoriented parts.

- Quiet Operation: Because of the mechanical motion of our step feeders, noise levels are significantly lower than that of vibratory feeders.

- Gentle Part Handling: Because there is no vibration, part abrasion in a step feeder is significantly reduced. With the simple orientation technique of the step feeder lifting a single row of parts out of the bin, and final orientation performed on a linear feeder, there is little to no wear to the parts being fed. This makes a step feeder ideal for feeding fragile parts.

- Extremely Durable: The simple linear motion of the step and the non-abrasive interaction with the parts being fed ensure that our step feeders will operate for years with minimal maintenance.

Custom (tooled) configurations

Our step feeders can be tooled to your specifications, allowing for a turn-key parts feeding solution. A tooled step feeder includes the sensors and controls that are included with an untooled unit, and the linear feeder is tooled to orient the parts to your specification. Other options available on tooled step feeders include:

- Prefeeders with automatic metering of parts into the step feeder bin, increasing bulk part storage capacity.

- Linear feeders for returning rejected parts to bulk storage.

- Bulk part level sensors.

- Part escapement and isolation devices.

- Part position sensors (part-in-place, high track, etc.)

- Custom sensor and control packages.

Downloads

Performance Feeders Tri-Fold Brochure

Step Feeder Brochure

Step Feeder Rack Card

PFS1 Step Feeder Brochure

PFSM Mini Step Feeder Rack Card