Step Feeder Orients 2 Different Sizes of Automotive Magnets

Jump to: System Specifications || Quote Request Form || Download Flier

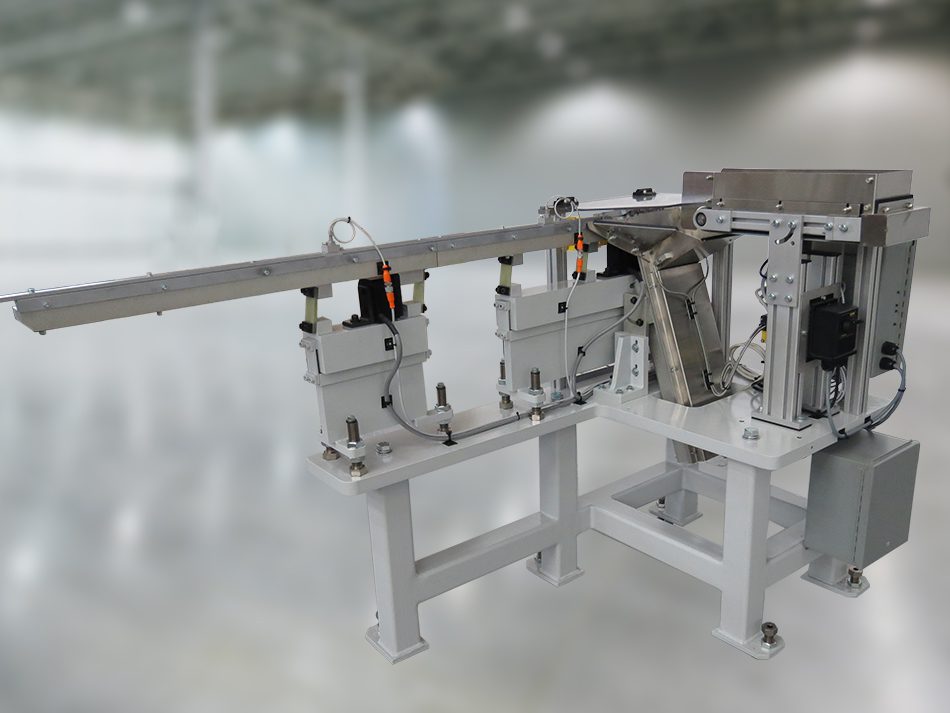

This system was designed to feed 2 sizes of magnets being assembled into an automotive product. A step feeder was chosen for space savings and durability.

View this short video that demonstrates the automotive parts as they are lifted from the step feeder bin onto the vibratory feeder track. Parts are continuously fed into the step feeder bin by the belt conveyor prefeeder, which is monitored by a photoelectric sensor that turns on the prefeeder as needed. The correct parts level on the inline vibratory feeder track is maintained by proximity sensors. Incorrectly sized parts are ejected from the system into the yellow bin.

System specifications

- Feed rate: 15 parts per minute

- Input voltage: 120V, 60 Hz.

- Step Feeder:

- Performance Feeders single-step feeder with 6″ wide x 1/2″ thick step.

- Electric drive.

- Delrin-lined bin.

- Hinged Lexan cover over bin.

- Vibratory orienting straight line track:

- 60″ long.

- Hardened and plated tool steel part contact surfaces.

- Powered by 2-spring and 3-spring vibratory inline drivers.

- Prefeeder:

- 1/4 cu. ft. bulk parts capacity.

- Auto-Kinetics standard duty belt conveyor, 200mm wide x 24″ long.

- 1/30 HP 90 VDC motor.

- Stainless steel bin.

- Controls:

- Standard Performance Feeders controls for step feeder and inline drivers, mounted in custom enclosure and junction box.

- Dart #15DVE for prefeeder conveyor.

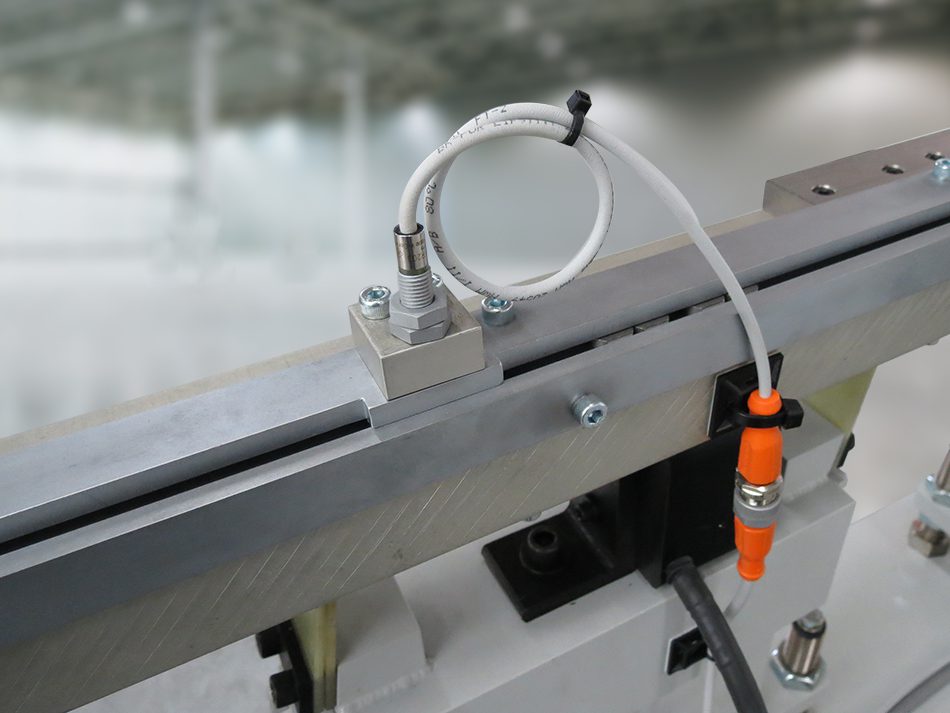

- Sensors provided:

- High track proximity sensor on vibratory inline: Controls step feeder, turning on when the parts level in the track drops below the sensor.

- Low track proximity sensor on vibratory inline: Provides signal to the customer’s control system when the parts level in the track drops below the sensor.

- Photoelectric sensor on step feeder bin: Controls prefeeder conveyor, automatically maintaining the proper parts level in the step feeder bin.

- Mounting surface: 1.25″ thick steel plate with 5-leg welded frame and leveling screws.

Downloads

Performance Feeders Tri-Fold Brochure

Step Feeder Brochure

Step Feeder Rack Card

PFS1 Step Feeder Brochure

PFSM Mini Step Feeder Rack Card