Featuring a vertical elevating prefeeder and high speed gravity roller tracks, this centrifugal feed system was developed to feed and orient medical product in excess of 800 ppm and built to run 24/7 in a continuous production environment, while using the smallest footprint possible and preserving the integrity of the parts being fed.

Count and Batch Packaging Conveyor Belt-Vibratory Bowl System

This custom feed system featured a vibratory bowl, designed to orient various sizes of bearing cages while also sorting and rejecting mixed product, and a count and batch conveyor which counted a pre-set number of selected product into the customer’s bulk packaging. The system required a vibratory feeder bowl with tooling designed for multiple products, a custom conveyor tooled to count product at its exit, a roller conveyor to stage the customer’s packaging, and programmable counting electronics to allow the customer to pre-set a package quantity which varied from product to product.

Belt Conveyor System with Airlock Chamber for Medical Packaging Operation

We were approached by a medical device manufacturer who needed a solution for moving empty packages from a warehouse into a cleanroom for packaging with product, then moving the full packages back into the warehouse for storage and shipment. They required continual movement of product between the warehouse and the cleanroom while maintaining the integrity of the cleanroom environment.

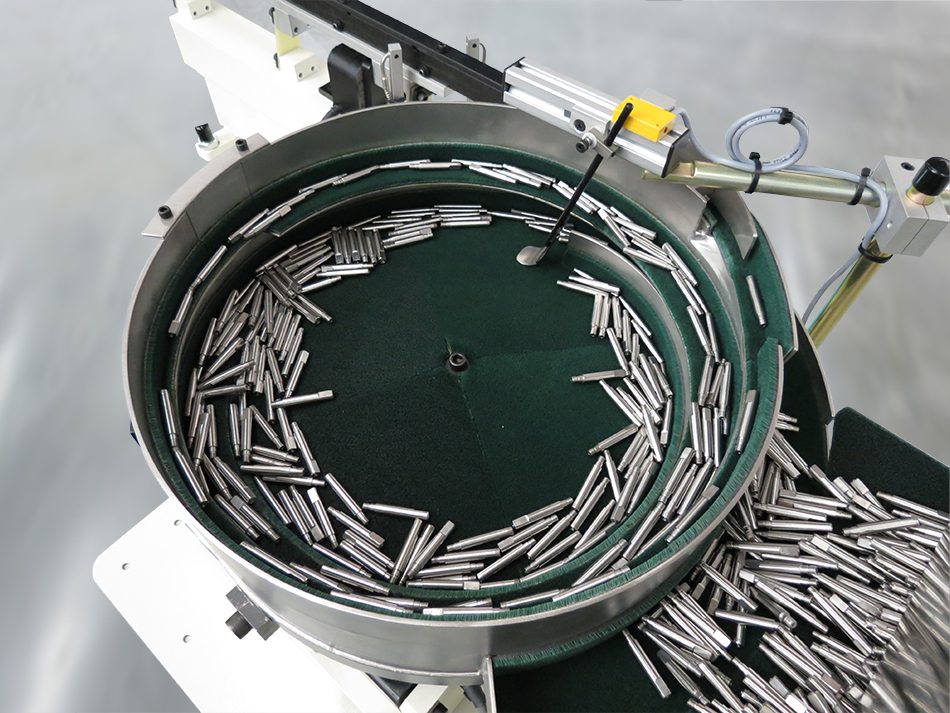

Vibratory Feeder with Gentle Parts Handling Features Minimizes Damage

This Brushlon-lined vibratory bowl feeding system was designed to feed two lengths of a polished steel shaft being assembled into a consumer product. Maintaining the cosmetic integrity of the parts was of utmost importance, so we designed a vibratory feed system that minimized the possibility of damage to the parts.

Turn-Key Vibratory Feeder With Bad Part Reject Feeds 2 Part Types into Assembly Line.

This vibratory feeder with custom conveyor belt tracking was designed to feed 2 styles of plastic parts into a consumer appliance assembly operation. The application required 4 lines of parts (2 lines of a left-hand version and 2 lines of a right-hand version), with each line alternating between the left-hand and right-hand part version. Each bowl feeder had to allow for the possibility of the wrong part being in the system, and an isolation mechanism was required so that 2 parts could be picked up from each line simultaneously.

Vibratory Feeder With Integrated Optical Inspection System Orients Parts Based On Internal Features

This vibratory feed system was designed to feed a metal washer into a machine assembling a consumer product. While flat, round parts like washers are normally easy to feed, this part had a small indentation on one side that needed to be oriented facing down. A Vision System checked the part for correct orientation before discharging it onto a straight-line track and into the customer’s assembly station.

FDA-Approved Stainless Steel Timing Conveyor Belt For Pharmaceutical Packaging

This custom timing belt conveyor was designed to feed pharmaceutical bottles through a pharmaceutical packaging operation.This pharmaceutical grade timing belt conveyor included complete stainless steel construction with FDA approved plastic side rails and a urethane timing belt.

Step Feeder Orients and Feeds Fragile Glass Light Bulbs

This system was designed to feed a low voltage light bulb into an automotive assembly operation. A step feeder was chosen due because its gentle part handling characteristics would minimize the chance of breaking the parts.

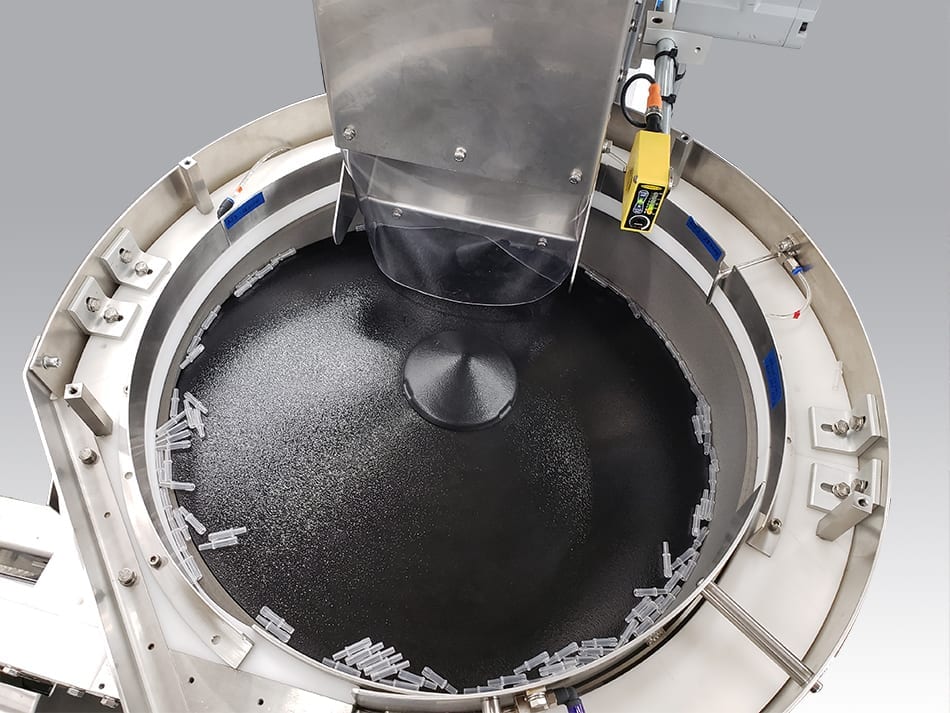

10-Line Vibratory Feeder System for Medical Manufacturing

This vibratory feeder was designed to feed three different styles of cylindrical plastic parts being assembled into a medical product. The parts were all the same diameter with slightly different heights. Four lines of parts ran out of the bowls then were merged into two lines feeding a vibratory track.

Vibratory Bowl Feeder with Optical Inspection System

This application required feeding 3 different lengths of a small steel shaft into a centerless grinding machine. Parts were oriented in the vibratory bowl and monitored for 100% accuracy by a vision system. Parts were discharged onto an Auto-Kinetics belt conveyor which moved the parts into our customer’s centerless grinding machine.