This vibratory feeder was designed to feed three different styles of cylindrical plastic parts being assembled into a medical product. The parts were all the same diameter with slightly different heights. Four lines of parts ran out of the bowls then were merged into two lines feeding a vibratory track.

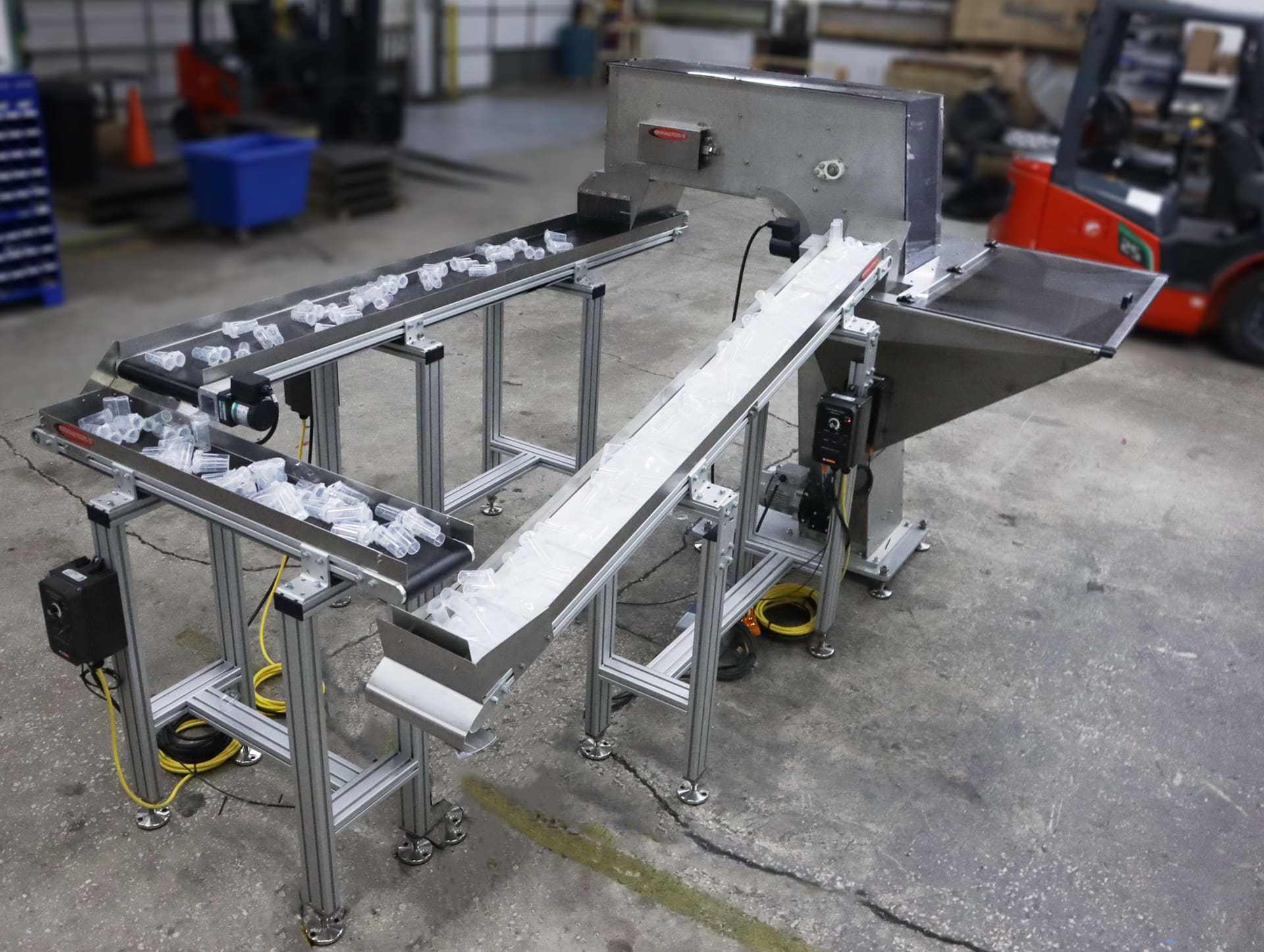

Flexible Feeder with Recirculating Conveyor for Medical Vial

This Flexible Feeding solution was designed to feed double and singly wrapped medical vials for robotic selection at 100PPM. This system includes both belted and cleated conveyors, bin sensors to detect low parts supply, stack light alerts, and a robotic inspection system.

Slant Disc Feeder: Affordable, Cost-Effective, Space-Saving

Space-saving and affordable, the Slant Disc Feeder carries medical product into the assembly line at the rate of 5 PPM. The vertical Slant Disc saves space and can run at speeds from 5PPM to 60PPM.

Centrifugal System for Medical Plunger and Barrel

Most barrel and plunger feed systems are relatively simple to tool as the products typically have features that allow the product to hang in gauge rollers quickly and easily. The one caveat to using this type of system is that, even though the tooling is simple, the units are required to be tilted at an angle of 10 or more degrees, to allow the product to move forward at a rapid pace. Limitations in the ceiling height required a creative solution that reduced the overall height without affecting performance.

Container Unscrambler for Medical Packaging

Our customer presented us a bottle with a geometric shape that presented several challenges during the feeding process. The tacky plastic material slowed the feed rate substantially and created high friction, which lowered the loading ratio. We designed acentrifugal solution that provided a 100% load ratio, resulting in higher feed rates at lower RPMs and allowing for a smaller system footprint which saved manufacturing floor space.

Medical Parts Vibratory Feed System with Optical Inspection

This vibratory feeder was designed to feed a plastic medical component into a machine assembling a medical testing product. While these parts were easy to pre-orient, the final orientation could not be obtained reliably mechanically so a vision system was used to verify proper orientation and reject product that did not meet the orientation criteria.

High Speed Centrifugal System Feeds Medical Product

Featuring a vertical elevating prefeeder and high speed gravity roller tracks, this centrifugal feed system was developed to feed and orient medical product in excess of 800 ppm and built to run 24/7 in a continuous production environment, while using the smallest footprint possible and preserving the integrity of the parts being fed.

Belt Conveyor System with Airlock Chamber for Medical Packaging Operation

We were approached by a medical device manufacturer who needed a solution for moving empty packages from a warehouse into a cleanroom for packaging with product, then moving the full packages back into the warehouse for storage and shipment. They required continual movement of product between the warehouse and the cleanroom while maintaining the integrity of the cleanroom environment.

FDA-Approved Stainless Steel Timing Conveyor Belt For Pharmaceutical Packaging

This custom timing belt conveyor was designed to feed pharmaceutical bottles through a pharmaceutical packaging operation.This pharmaceutical grade timing belt conveyor included complete stainless steel construction with FDA approved plastic side rails and a urethane timing belt.

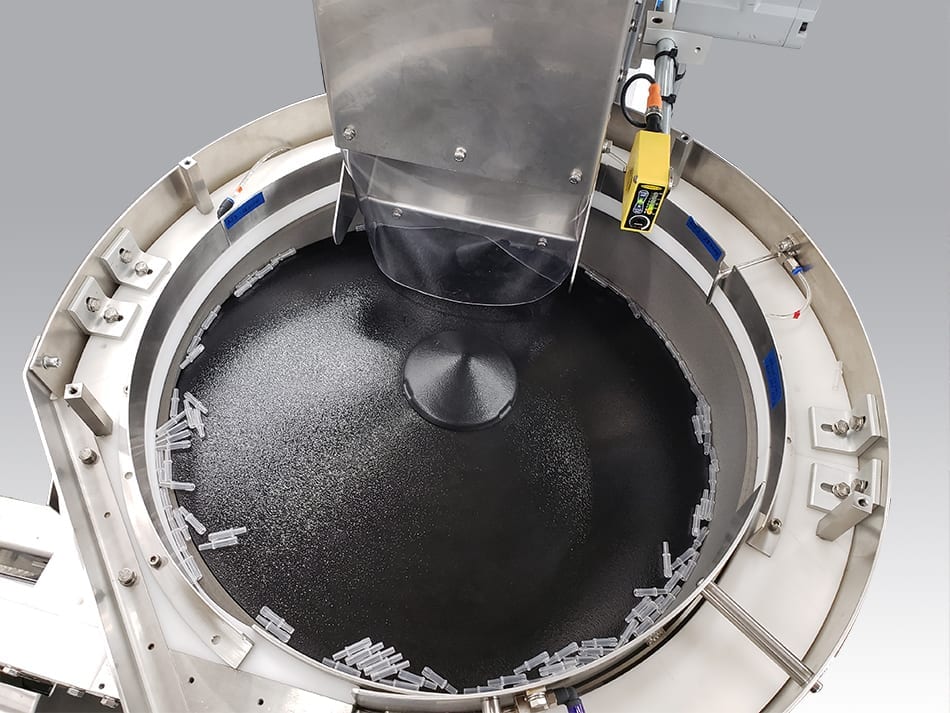

Centrifugal Feeder Feeds 1300 Pharmaceutical Parts per Minute

This system was designed for a pharmaceutical product manufacturer who needed to orient and feed two types of round plastic parts at a rate of 1300 parts per minute. We used a centrifugal bowl feeder for this project because of the high feed rate requirement.