This custom feed system featured a vibratory bowl, designed to orient various sizes of bearing cages while also sorting and rejecting mixed product, and a count and batch conveyor which counted a pre-set number of selected product into the customer’s bulk packaging. The system required a vibratory feeder bowl with tooling designed for multiple products, a custom conveyor tooled to count product at its exit, a roller conveyor to stage the customer’s packaging, and programmable counting electronics to allow the customer to pre-set a package quantity which varied from product to product.

Turn-Key Vibratory Feeder With Bad Part Reject Feeds 2 Part Types into Assembly Line.

This vibratory feeder with custom conveyor belt tracking was designed to feed 2 styles of plastic parts into a consumer appliance assembly operation. The application required 4 lines of parts (2 lines of a left-hand version and 2 lines of a right-hand version), with each line alternating between the left-hand and right-hand part version. Each bowl feeder had to allow for the possibility of the wrong part being in the system, and an isolation mechanism was required so that 2 parts could be picked up from each line simultaneously.

Step Feeder Orients and Feeds Fragile Glass Light Bulbs

This system was designed to feed a low voltage light bulb into an automotive assembly operation. A step feeder was chosen due because its gentle part handling characteristics would minimize the chance of breaking the parts.

Vibratory Bowl Feeder with Optical Inspection System

This application required feeding 3 different lengths of a small steel shaft into a centerless grinding machine. Parts were oriented in the vibratory bowl and monitored for 100% accuracy by a vision system. Parts were discharged onto an Auto-Kinetics belt conveyor which moved the parts into our customer’s centerless grinding machine.

Step Feeder Orients Differently-Sized Automotive Parts

This system was designed to feed 2 sizes of magnets being assembled into an automotive product. A step feeder was chosen for space savings and durability. This system features a step feeder bin, proximity sensors, and a pre-feeder conveyor belt.

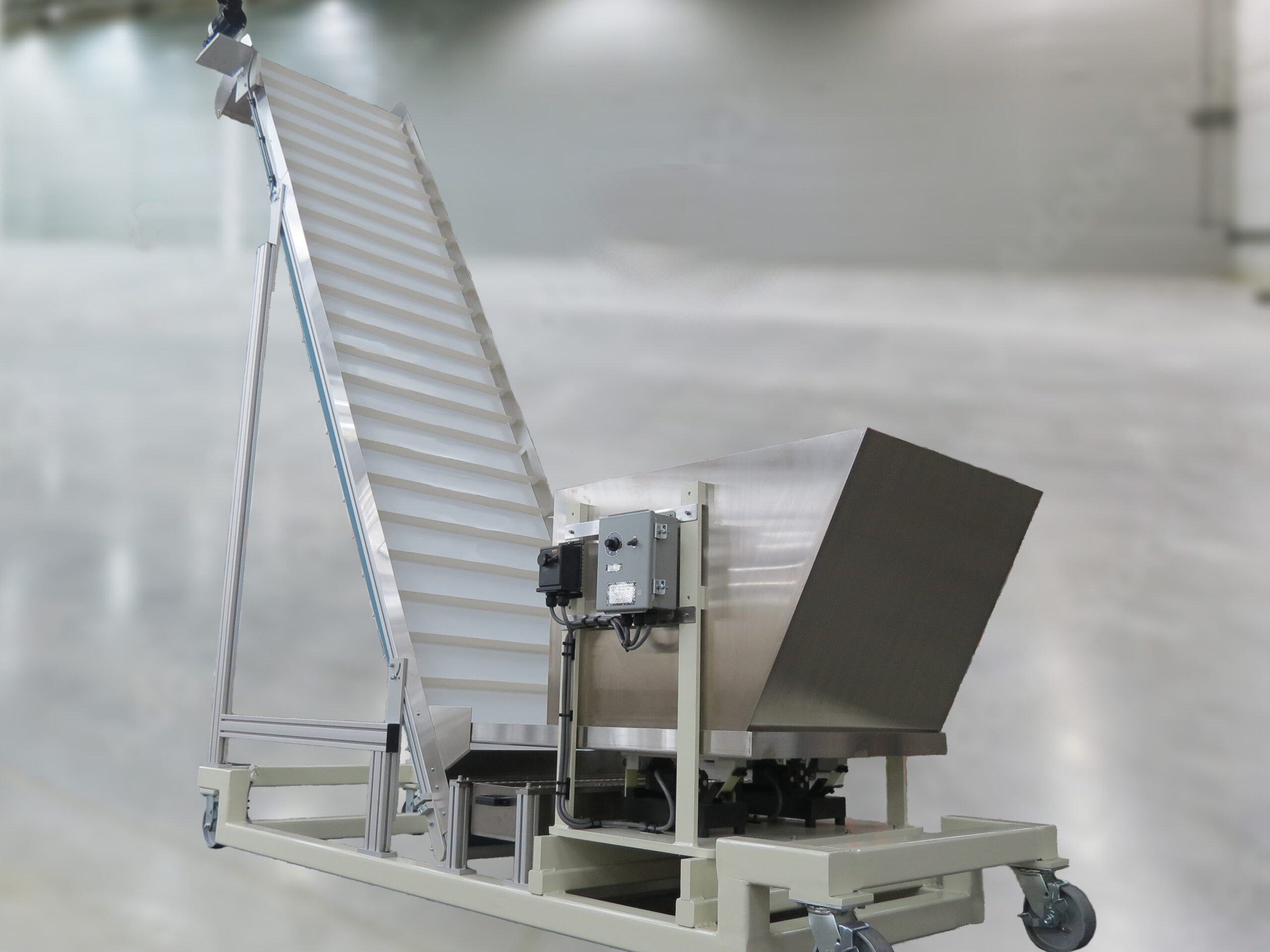

Elevator Belt Conveyor System with Storage Hopper for Food Packaging

This system was designed for a food manufacturer who needed to move a whole-grain snack product to a packaging operation, which required the product to be delivered 10′ off the floor. The manufacturer needed bulk product storage at floor level and a way to remove as much small and broken pieces of product as possible before moving into the packaging operation.