Featuring a vertical elevating prefeeder and high speed gravity roller tracks, this centrifugal feed system was developed to feed and orient medical product in excess of 800 ppm and built to run 24/7 in a continuous production environment, while using the smallest footprint possible and preserving the integrity of the parts being fed.

Slant Disc Feeder: Affordable, Cost-Effective, Space-Saving

Space-saving and affordable, the Slant Disc Feeder carries medical product into the assembly line at the rate of 5 PPM. The vertical Slant Disc saves space and can run at speeds from 5PPM to 60PPM.

V Belt Centrifugal Feeder for Electrical Covers

Centrifugal Feeder orients decorative electrical covers as they enter the assembly process with a gentle handling that protects the delicate material.

Centrifugal System for Medical Plunger and Barrel

Most barrel and plunger feed systems are relatively simple to tool as the products typically have features that allow the product to hang in gauge rollers quickly and easily. The one caveat to using this type of system is that, even though the tooling is simple, the units are required to be tilted at an angle of 10 or more degrees, to allow the product to move forward at a rapid pace. Limitations in the ceiling height required a creative solution that reduced the overall height without affecting performance.

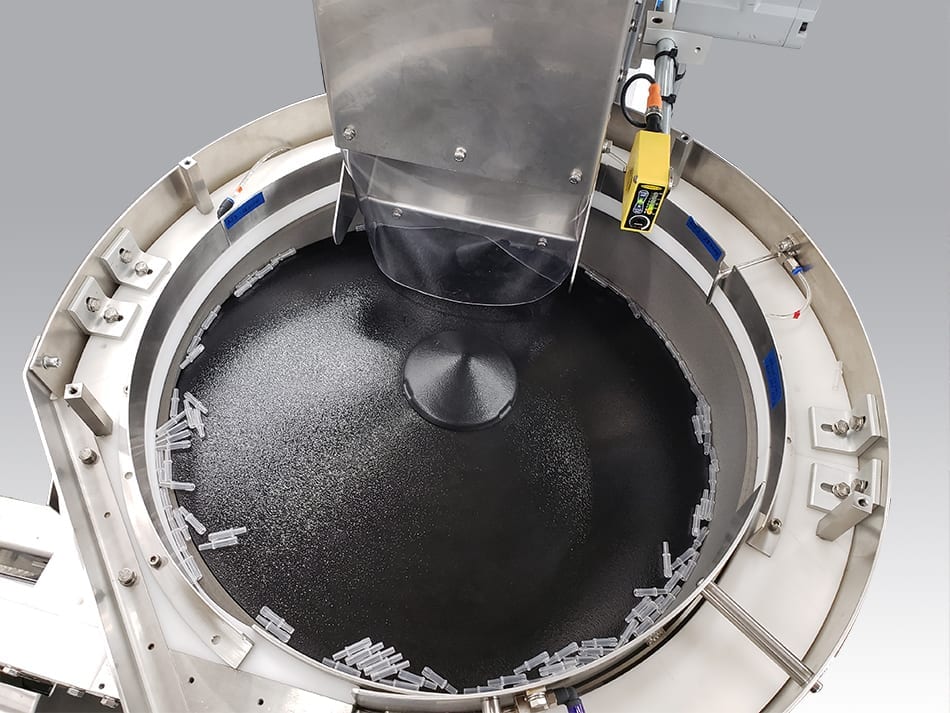

Centrifugal Feeder Feeds 1300 Pharmaceutical Parts per Minute

This system was designed for a pharmaceutical product manufacturer who needed to orient and feed two types of round plastic parts at a rate of 1300 parts per minute. We used a centrifugal bowl feeder for this project because of the high feed rate requirement.