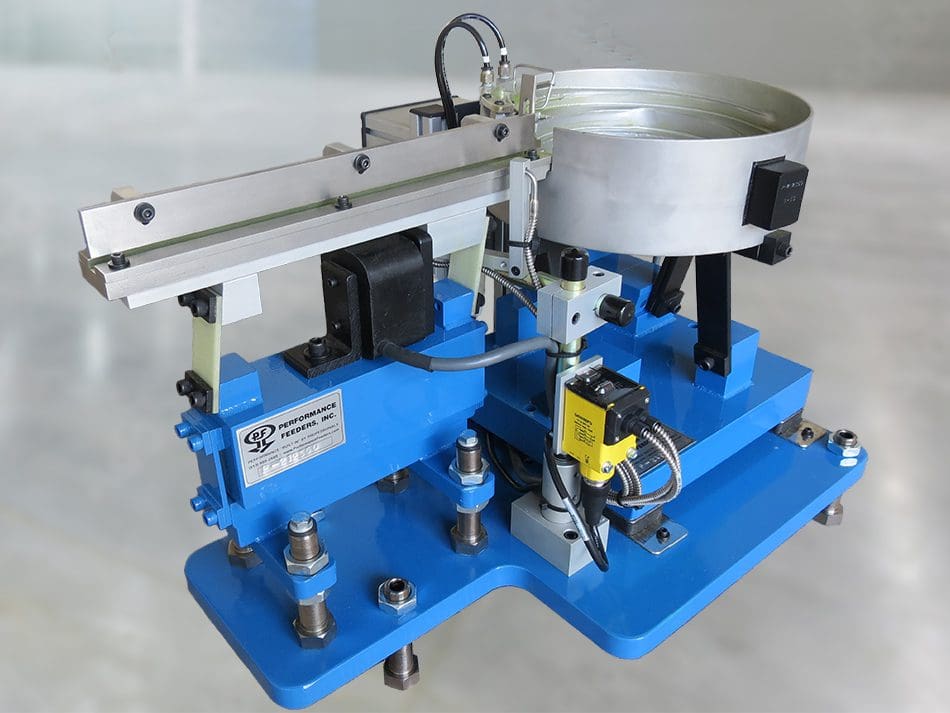

The versatile outside-tooled vibratory feeder bowl is the foundation of this part feeding solution designed to orient bolt blanks for our customer, a manufacturer of fastening products. The vision system verifies that each bolt blank is in the required position. A C-track mounted at the end of the conveyor delivers the parts to the customer’s downstream operation at 40 parts per minute.

Count and Batch Packaging Conveyor Belt-Vibratory Bowl System

This custom feed system featured a vibratory bowl, designed to orient various sizes of bearing cages while also sorting and rejecting mixed product, and a count and batch conveyor which counted a pre-set number of selected product into the customer’s bulk packaging. The system required a vibratory feeder bowl with tooling designed for multiple products, a custom conveyor tooled to count product at its exit, a roller conveyor to stage the customer’s packaging, and programmable counting electronics to allow the customer to pre-set a package quantity which varied from product to product.

Vibratory Bowl Feeder with Optical Inspection System

This application required feeding 3 different lengths of a small steel shaft into a centerless grinding machine. Parts were oriented in the vibratory bowl and monitored for 100% accuracy by a vision system. Parts were discharged onto an Auto-Kinetics belt conveyor which moved the parts into our customer’s centerless grinding machine.

Vibratory Feeder Bowl System with Center Discharge

This vibratory parts feeding system was designed to feed two sizes of a part used in air conditioner desiccant systems. The simple cylindrical shape of the parts allowed the use of a “cascade” type bowl feeder, where all part orientation is performed within the inside diameter of the bowl. This eliminated tooling construction on the outside of the bowl, which along with the right-angle discharge into the vibratory track, resulted in a compact vibratory feed system that met our customer’s space requirements.