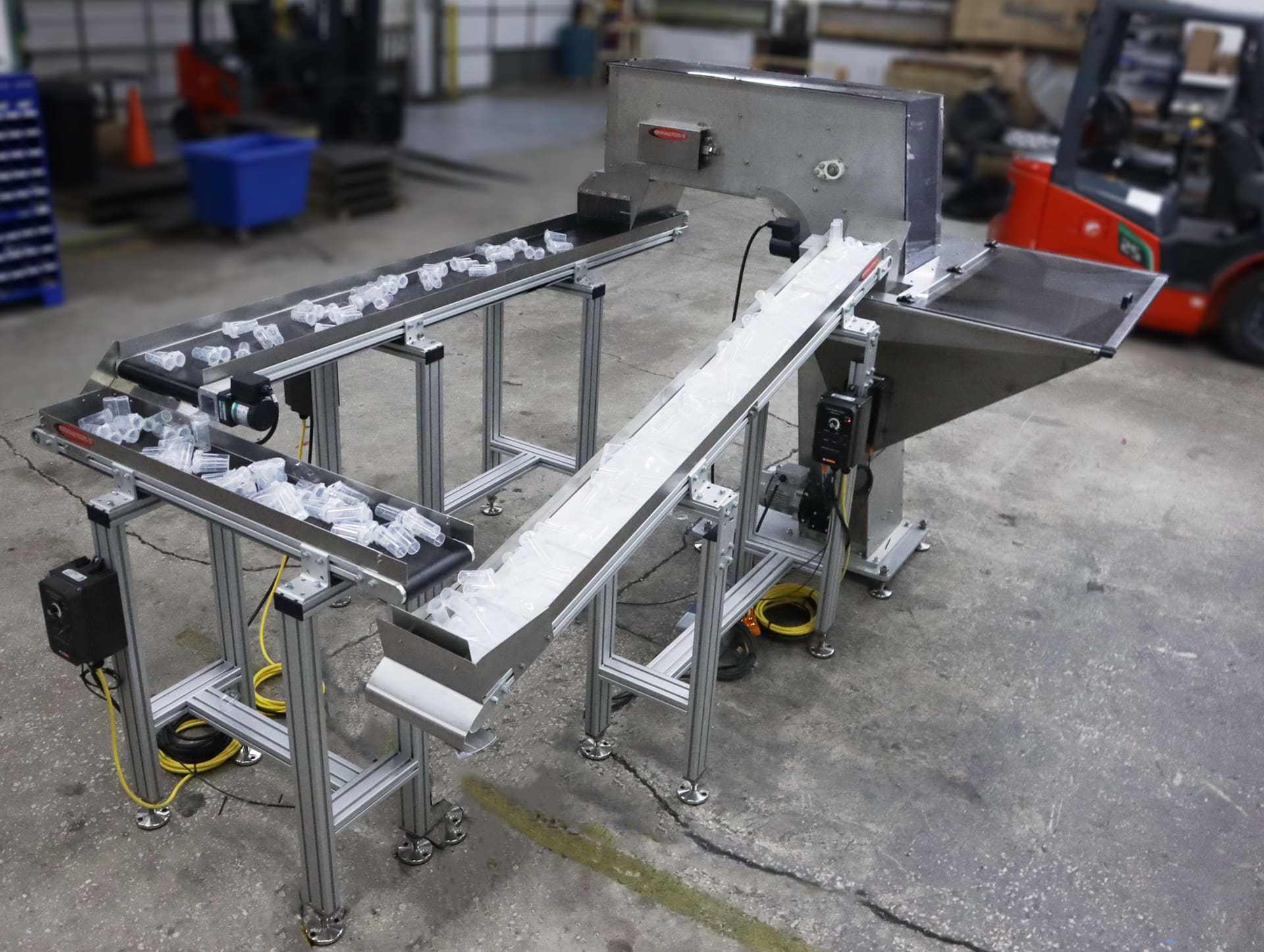

This Flexible Feeding solution was designed to feed double and singly wrapped medical vials for robotic selection at 100PPM. This system includes both belted and cleated conveyors, bin sensors to detect low parts supply, stack light alerts, and a robotic inspection system.

Count and Batch Packaging Conveyor Belt-Vibratory Bowl System

This custom feed system featured a vibratory bowl, designed to orient various sizes of bearing cages while also sorting and rejecting mixed product, and a count and batch conveyor which counted a pre-set number of selected product into the customer’s bulk packaging. The system required a vibratory feeder bowl with tooling designed for multiple products, a custom conveyor tooled to count product at its exit, a roller conveyor to stage the customer’s packaging, and programmable counting electronics to allow the customer to pre-set a package quantity which varied from product to product.

Belt Conveyor System with Airlock Chamber for Medical Packaging Operation

We were approached by a medical device manufacturer who needed a solution for moving empty packages from a warehouse into a cleanroom for packaging with product, then moving the full packages back into the warehouse for storage and shipment. They required continual movement of product between the warehouse and the cleanroom while maintaining the integrity of the cleanroom environment.

FDA-Approved Stainless Steel Timing Conveyor Belt For Pharmaceutical Packaging

This custom timing belt conveyor was designed to feed pharmaceutical bottles through a pharmaceutical packaging operation.This pharmaceutical grade timing belt conveyor included complete stainless steel construction with FDA approved plastic side rails and a urethane timing belt.

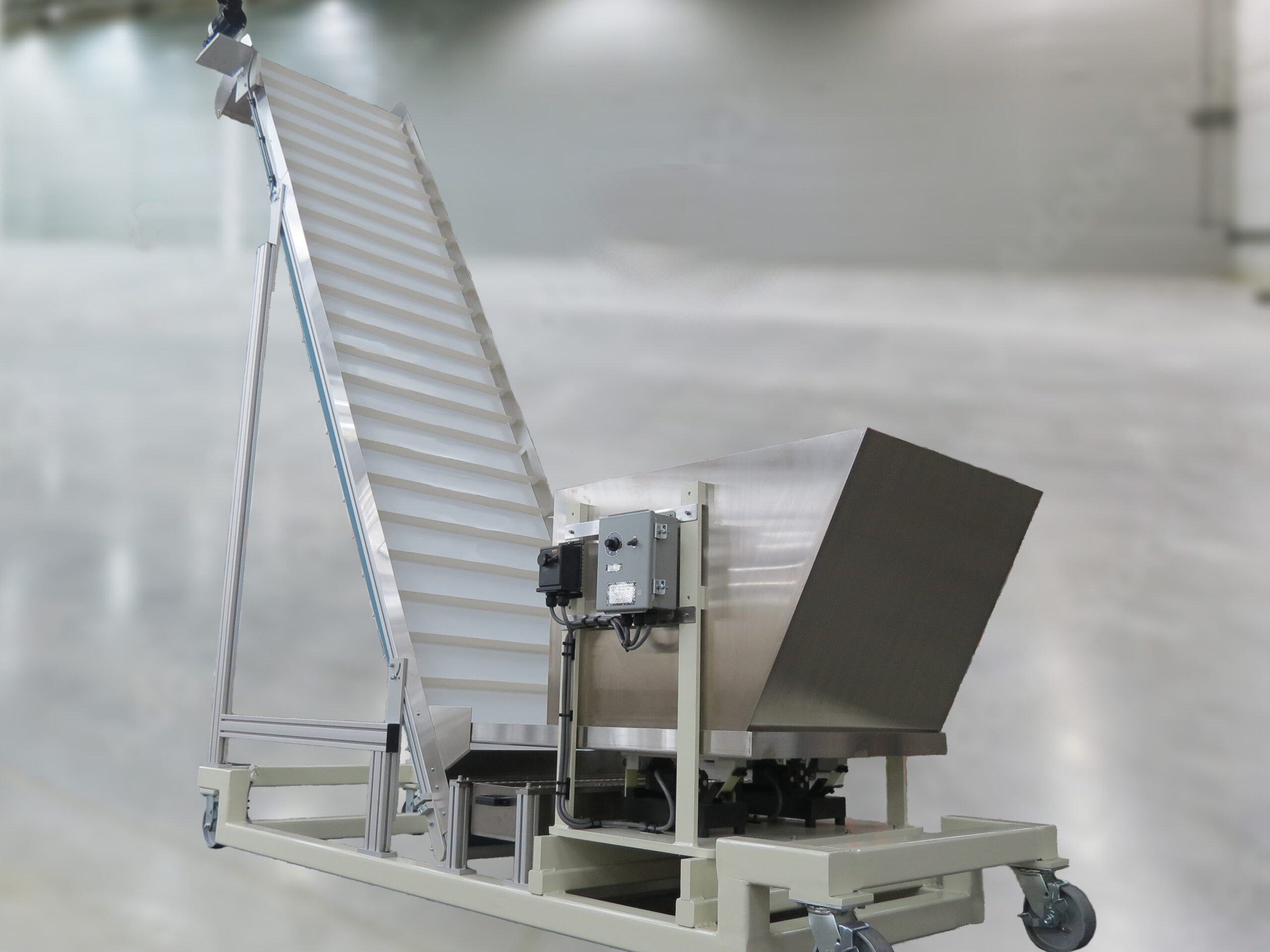

Elevator Belt Conveyor System with Storage Hopper for Food Packaging

This system was designed for a food manufacturer who needed to move a whole-grain snack product to a packaging operation, which required the product to be delivered 10′ off the floor. The manufacturer needed bulk product storage at floor level and a way to remove as much small and broken pieces of product as possible before moving into the packaging operation.

High-Precision, FDA Approved Cleated Timing Belt Conveyor System

This custom conveyor system was designed to transfer blister packs of medical products between machinery assembling the blister packs and machinery packaging the packs into cartons. Packs were loaded onto the conveyor at the entrance end and shuttled sideways into a packaging machine at the discharge end. The high-precision requirements of this application necessitated the use of a custom timing belt conveyor.

Conveyor Belt System with Automatic Tray Loading

This Custom Conveyor System was designed for a manufacturer who needed to load empty trays with parts for an automatic assembly operation. Empty trays were loaded onto a powered Auto-Kinetics heavy-duty belt conveyor. Upon reaching the end of the belt conveyor, a pneumatic slide pushed a single tray sideways onto a robotic loading station. Once in position, a second pneumatic slide clamped the tray in place for loading.