This Custom Conveyor System was designed for a manufacturer who needed to load empty trays with parts for an automatic assembly operation. Empty trays were loaded onto a powered Auto-Kinetics heavy-duty belt conveyor. Upon reaching the end of the belt conveyor, a pneumatic slide pushed a single tray sideways onto a robotic loading station. Once in position, a second pneumatic slide clamped the tray in place for loading.

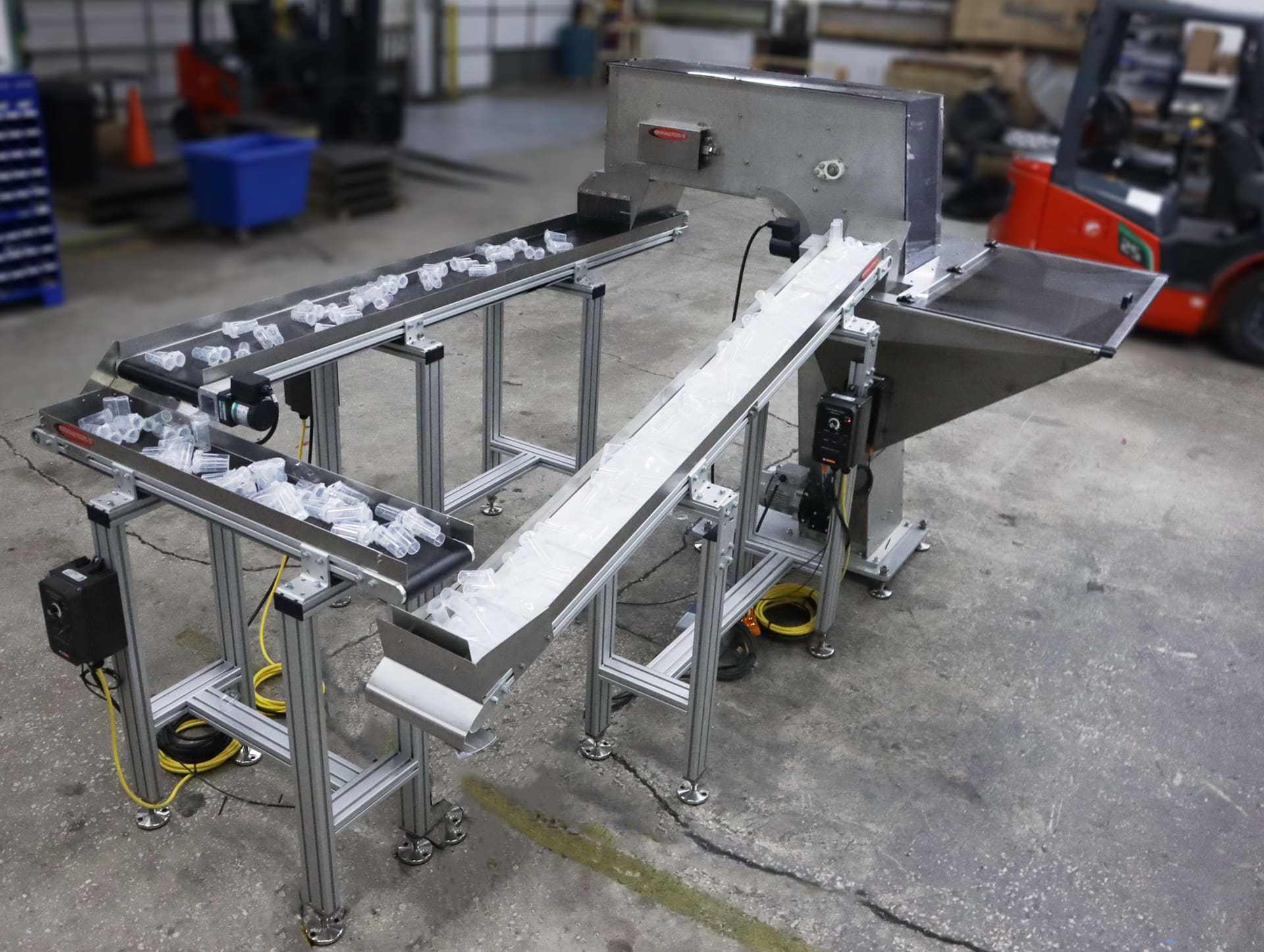

Flexible Feeder with Recirculating Conveyor for Medical Vial

This Flexible Feeding solution was designed to feed double and singly wrapped medical vials for robotic selection at 100PPM. This system includes both belted and cleated conveyors, bin sensors to detect low parts supply, stack light alerts, and a robotic inspection system.

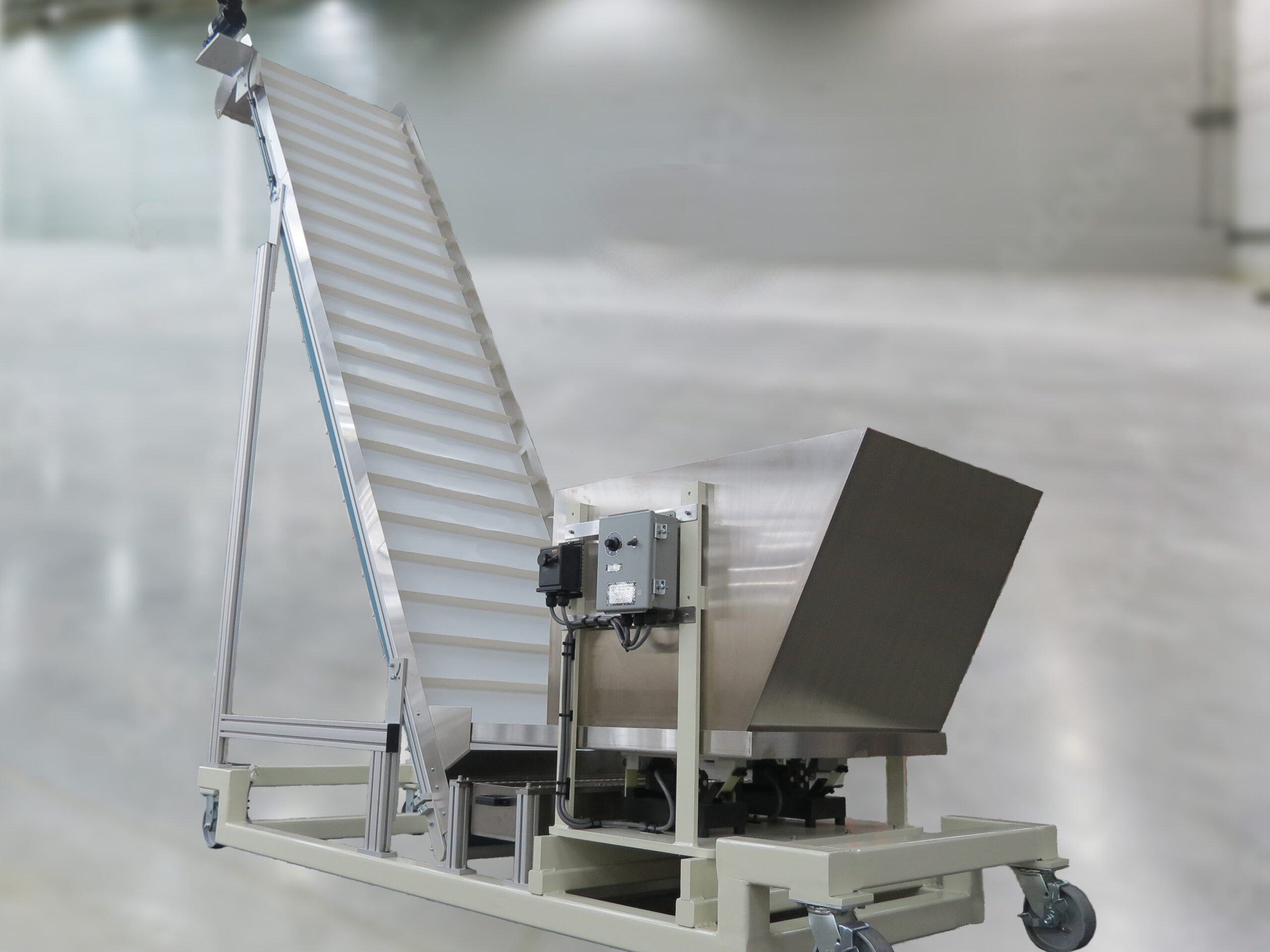

Z Belt Conveyor for Automotive Part

This Heavy-duty Z Style Conveyor was constructed as a feeding solution for an automotive manufacturer. The conveyance system transferred a tubular metal part to the customer’s receiving assembly equipment located at a higher elevation.

Belt Conveyor System with Airlock Chamber for Medical Packaging Operation

We were approached by a medical device manufacturer who needed a solution for moving empty packages from a warehouse into a cleanroom for packaging with product, then moving the full packages back into the warehouse for storage and shipment. They required continual movement of product between the warehouse and the cleanroom while maintaining the integrity of the cleanroom environment.

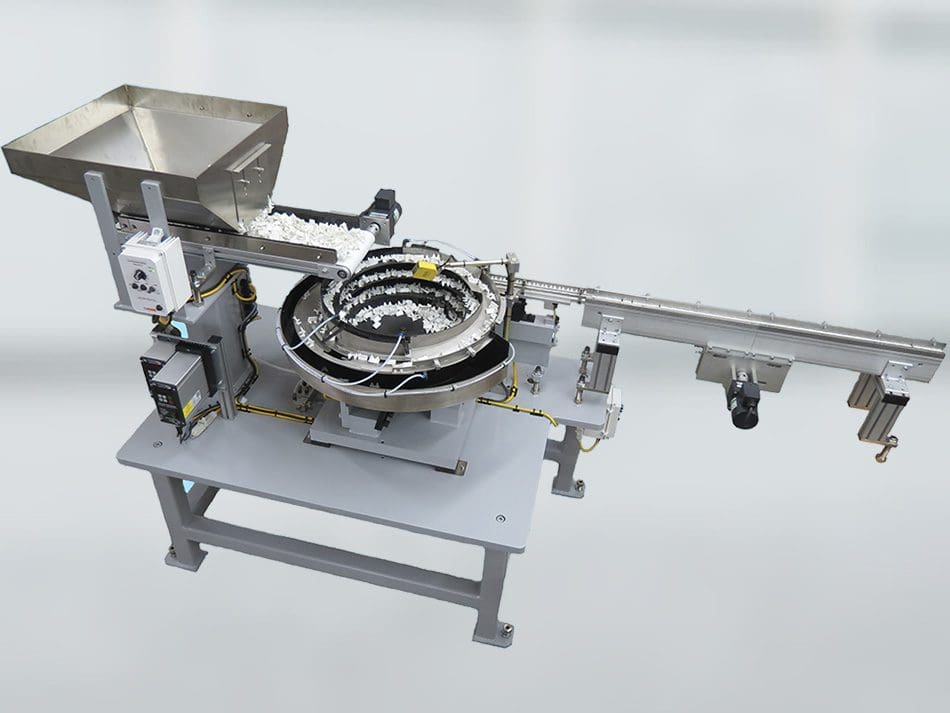

Turn-Key Vibratory Feeder With Bad Part Reject Feeds 2 Part Types into Assembly Line.

This vibratory feeder with custom conveyor belt tracking was designed to feed 2 styles of plastic parts into a consumer appliance assembly operation. The application required 4 lines of parts (2 lines of a left-hand version and 2 lines of a right-hand version), with each line alternating between the left-hand and right-hand part version. Each bowl feeder had to allow for the possibility of the wrong part being in the system, and an isolation mechanism was required so that 2 parts could be picked up from each line simultaneously.

FDA-Approved Stainless Steel Timing Conveyor Belt For Pharmaceutical Packaging

This custom timing belt conveyor was designed to feed pharmaceutical bottles through a pharmaceutical packaging operation.This pharmaceutical grade timing belt conveyor included complete stainless steel construction with FDA approved plastic side rails and a urethane timing belt.

Medical Packaging Belt Conveyor System

This conveyor belt system was designed for a medical device manufacturer who needed to package a medical product into boxes. This conveyor had a low-friction belt to allow the loaded boxes to be pushed across the belt perpendicular to the conveyor’s direction of travel.

Elevator Belt Conveyor System with Storage Hopper for Food Packaging

This system was designed for a food manufacturer who needed to move a whole-grain snack product to a packaging operation, which required the product to be delivered 10′ off the floor. The manufacturer needed bulk product storage at floor level and a way to remove as much small and broken pieces of product as possible before moving into the packaging operation.

Hybrid Vibratory Feeder – Conveyor System for Gentle Parts Handling

A component of a sensor for a consumer product was made of a plastic material that was susceptible to damage from vibration. The assembly operation also required that the parts be kept as clean as possible. We designed a custom parts feeding system that combined a vibratory feeder bowl and straight line track with belt conveyors to provide an effective solution to these unique design challenges.

High-Precision, FDA Approved Cleated Timing Belt Conveyor System

This custom conveyor system was designed to transfer blister packs of medical products between machinery assembling the blister packs and machinery packaging the packs into cartons. Packs were loaded onto the conveyor at the entrance end and shuttled sideways into a packaging machine at the discharge end. The high-precision requirements of this application necessitated the use of a custom timing belt conveyor.

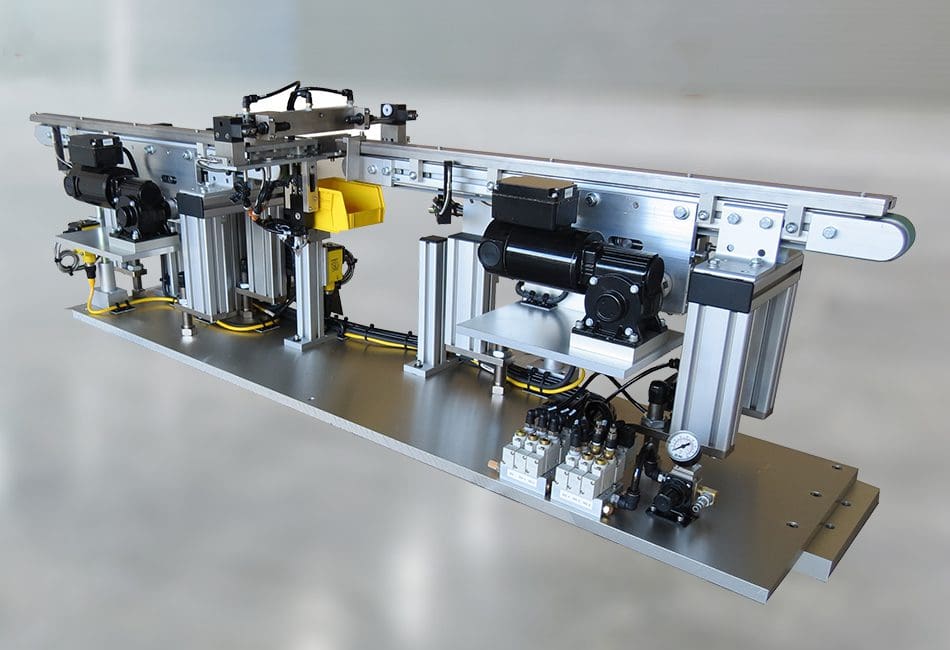

Conveyor Belt System Feeds Parts Using Optical Inspection

This custom conveyor system was retro-fitted to a vibratory feeder bowl to accommodate a part change that required a secondary inspection operation. The system consisted of a pair of Auto-Kinetics belt conveyors with custom tooling to maintain part orientation, and a 3-position shuttle mechanism between the conveyors.