Vibratory Feeder with Gentle Handling Features Minimizes Parts Damage

Jump to: System Specifications || Quote Request Form || Download Flier

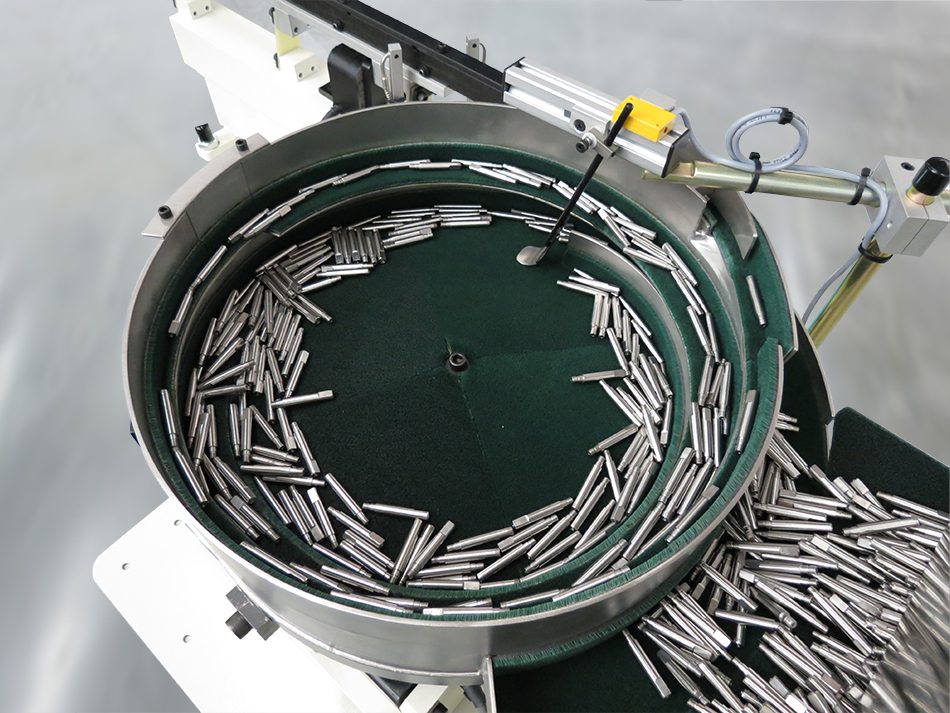

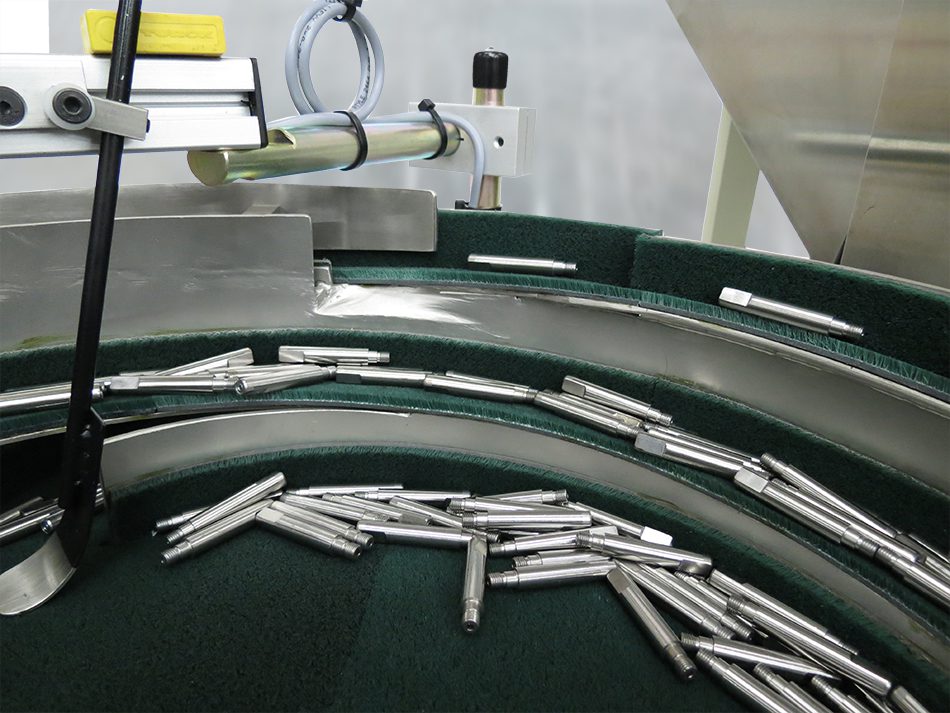

This vibratory bowl feeding system was designed to feed two lengths of a polished steel shaft being assembled into a consumer product. Maintaining the cosmetic integrity of the parts was of utmost importance, so we designed a vibratory feed system that minimized the possibility of damage to the parts.

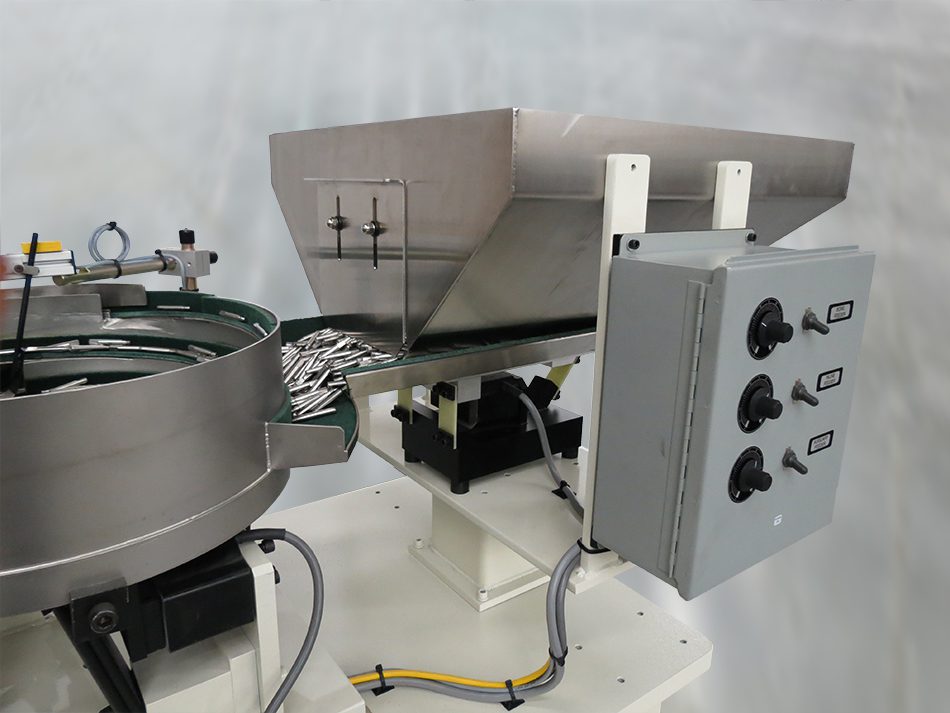

A vibratory stainless steel bulk supply hopper held 3 cu. ft. of bulk parts and automatically fed them into the feeder bowl as needed. The hopper tray was positioned to feed parts directly into the return pan, allowing the tray to be very close to the bowl surface, minimizing the possibility of damage to the parts from dropping into the bowl.

System specifications

- Feed Rate: 25 parts per minute

- Input voltage: 120V, 60 Hz.

- Vibratory bowl feeder:

- 18″ diameter.

- Counterclockwise rotation.

- Bead blasted stainless steel construction.

- Brushlon lining on all surfaces that parts contact.

- Purge gate for quick part changeover.

- Vibratory straight line track:

- 36″ long.

- Delrin and aluminum construction.

- Brushlon part running surface.

- 3-spring vibratory inline driver.

- Vibratory bulk supply hopper:

- 3 cu. ft. capacity with table mount.

- Stainless steel bin and tray.

- Brushlon lining on bin interior and tray.

- Hopper feeds into bowl return pan to minimize part drop.

- Controls:Performance Feeders PF-3R.

- Mounting surface: 1.25″ thick steel tables with 5 legs.

- Sensors provided:

- Photoelectric sensor on straight line track monitoring part level in track. Bowl only runs when parts are needed in the track, minimizing wear to parts and the bowl.

- Proximity sensor on hopper monitoring parts level in bowl. Hopper only runs when parts are needed in the bowl, minimizing wear to parts and the hopper.

Downloads

Performance Feeders Tri-Fold Brochure

Vibratory Feeder Bi-Fold Brochure

Vibratory Feeder Rack Card