Custom Vibratory Feeders

Vibratory Feeder System with Camera Vision Monitors Parts Orientation

The versatile outside-tooled vibratory feeder bowl is the foundation of this part feeding solution designed to orient bolt blanks for our customer, a manufacturer of fastening products. The vision system verifies that each bolt blank is in the required position. A C-track mounted at the end of the conveyor delivers the parts to the customer’s downstream operation at 40 parts per minute.

Read the Case Study >> Vibratory Feeder System with Camera Vision Monitors Parts Orientation

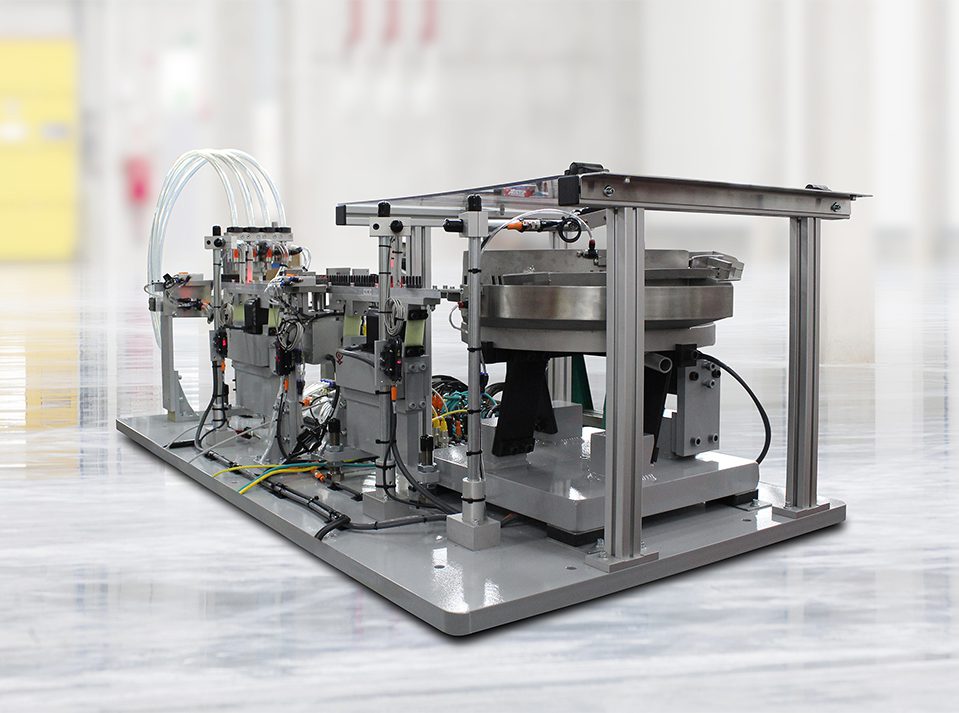

Robotics Increase Output of Flexible Part Feeding Solutions

The Performance Feeders Flex-Feeding platform is a revolutionary system that integrates robotics with our standard feeding solutions to increase output and improve accuracy as products are fed into your production system. These systems are easily re-tooled to match your next generation of product, bringing a new level of flexibility to your assembly line and lowering the upfront costs of redesigning an older product line or introducing a new one.

Read the Case Study >> Robotics Increase Output of Flexible Part Feeding Solutions

Vibratory Feeder with Rotary Inspection

This vibratory feed system includes a laser inspection station, a bowl level sensor, a track sensor, and a sorting indexer. Parts with an incorrect length are rejected while the correct parts are oriented threads-up in groups of 4.

Read the Case Study >> Vibratory Feeder with Rotary Inspection

Count and Batch Packaging Conveyor Belt-Vibratory Bowl System

This custom feed system featured a vibratory bowl, designed to orient various sizes of bearing cages while also sorting and rejecting mixed product, and a count and batch conveyor which counted a pre-set number of selected product into the customer’s bulk packaging. The system required a vibratory feeder bowl with tooling designed for multiple products, a custom conveyor tooled to count product at its exit, a roller conveyor to stage the customer’s packaging, and programmable counting electronics to allow the customer to pre-set a package quantity which varied from product to product.

Read the Case Study >> Count and Batch Packaging Conveyor Belt-Vibratory Bowl System

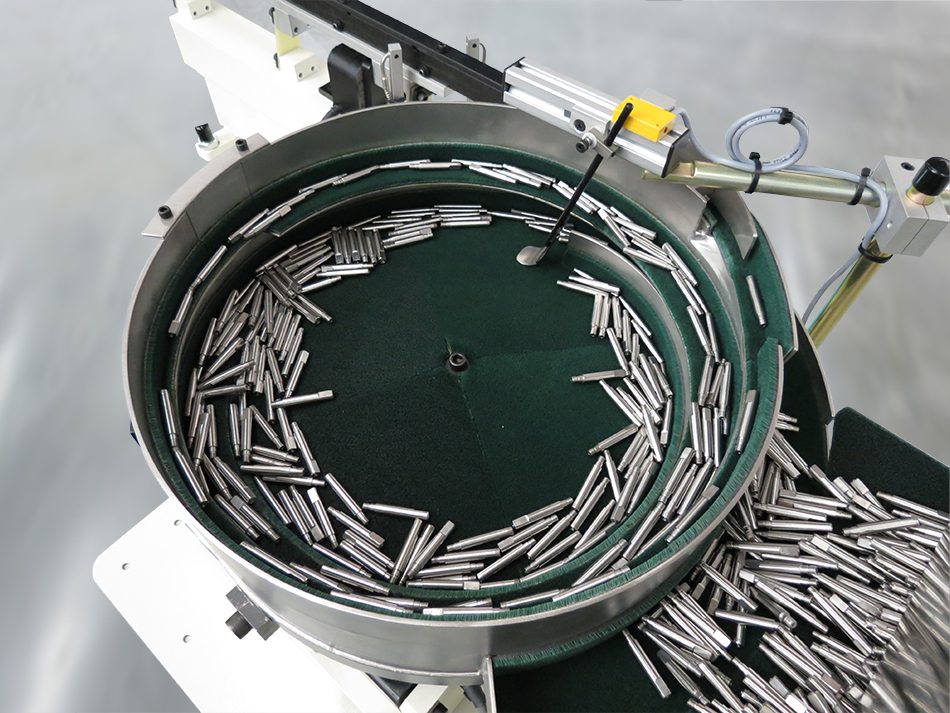

Vibratory Feeder with Gentle Parts Handling Features Minimizes Damage

This Brushlon-lined vibratory bowl feeding system was designed to feed two lengths of a polished steel shaft being assembled into a consumer product. Maintaining the cosmetic integrity of the parts was of utmost importance, so we designed a vibratory feed system that minimized the possibility of damage to the parts.

Read the Case Study >> Vibratory Feeder with Gentle Parts Handling Features Minimizes Damage

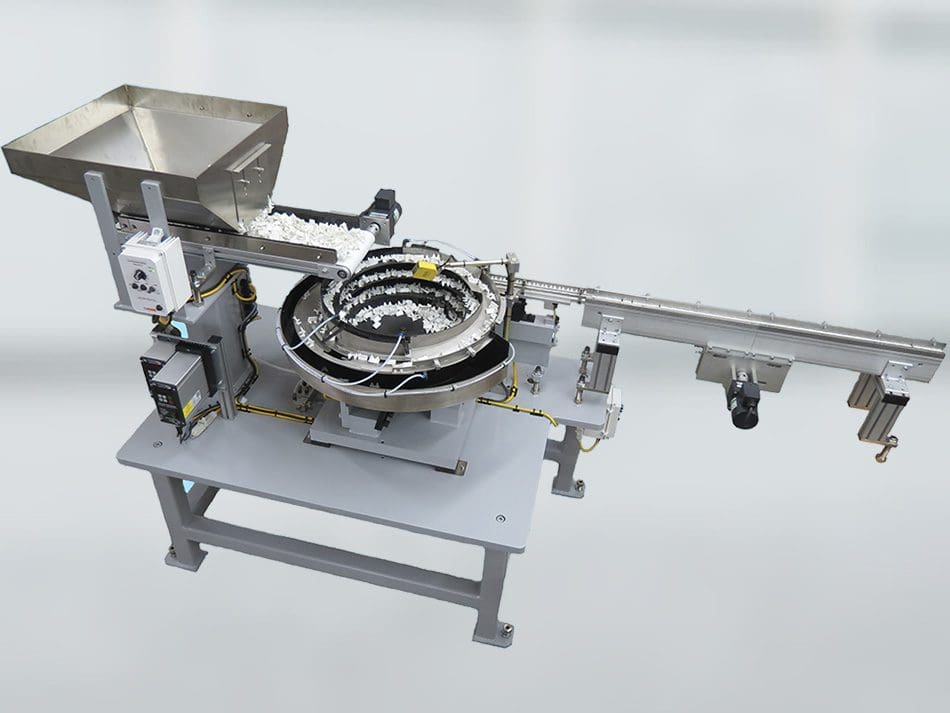

Turn-Key Vibratory Feeder With Bad Part Reject Feeds 2 Part Types into Assembly Line.

This vibratory feeder with custom conveyor belt tracking was designed to feed 2 styles of plastic parts into a consumer appliance assembly operation. The application required 4 lines of parts (2 lines of a left-hand version and 2 lines of a right-hand version), with each line alternating between the left-hand and right-hand part version. Each bowl feeder had to allow for the possibility of the wrong part being in the system, and an isolation mechanism was required so that 2 parts could be picked up from each line simultaneously.

Vibratory Feeder With Integrated Optical Inspection System Orients Parts Based On Internal Features

This vibratory feed system was designed to feed a metal washer into a machine assembling a consumer product. While flat, round parts like washers are normally easy to feed, this part had a small indentation on one side that needed to be oriented facing down. A Vision System checked the part for correct orientation before discharging it onto a straight-line track and into the customer’s assembly station.

10-Line Vibratory Feeder System for Medical Manufacturing

This vibratory feeder was designed to feed three different styles of cylindrical plastic parts being assembled into a medical product. The parts were all the same diameter with slightly different heights. Four lines of parts ran out of the bowls then were merged into two lines feeding a vibratory track.

Read the Case Study >> 10-Line Vibratory Feeder System for Medical Manufacturing

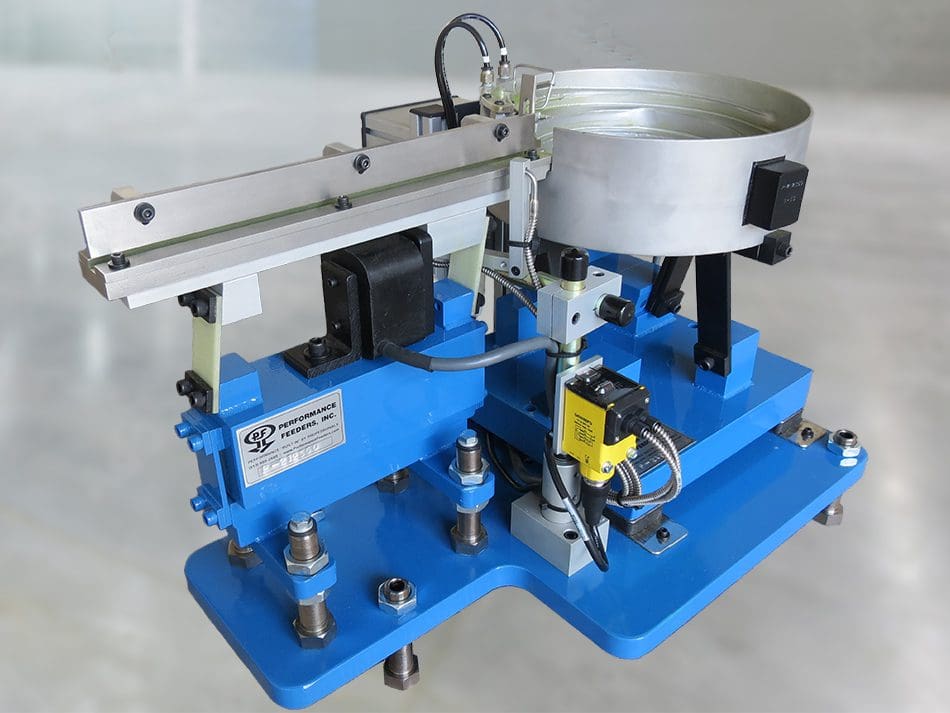

Vibratory Bowl Feeder with Optical Inspection System

This application required feeding 3 different lengths of a small steel shaft into a centerless grinding machine. Parts were oriented in the vibratory bowl and monitored for 100% accuracy by a vision system. Parts were discharged onto an Auto-Kinetics belt conveyor which moved the parts into our customer’s centerless grinding machine.

Read the Case Study >> Vibratory Bowl Feeder with Optical Inspection System

Vibratory Floating Mandrel Feed System Feeds Thin Metallic Washers

This system was designed for a consumer products manufacturer to feed two types of washers: A wavy spring washer and a fiber washer. Vibratory bowl feeders were used to orient both parts, and the feed systems were mounted on a common table to save space and cost.

Read the Case Study >> Vibratory Floating Mandrel Feed System Feeds Thin Metallic Washers

Vibratory Feeder for Medical and Pharmaceutical Applications

This vibratory bowl feeder system was designed to orient and feed 7 different types of plastic bottles into a pharmaceutical filling and packaging system. The bowl was built with FDA-grade 316 stainless steel. To ensure that all bowl surfaces were smooth, pit-free and resistant to dust collection.

Read the Case Study >> Vibratory Feeder for Medical and Pharmaceutical Applications

Vibratory Feeder Bowl Reliably Feeds O-Rings

Feeding o-rings in vibratory bowl systems has been historically problematic due to buildup of static electricity causing the parts to stick together and stick to the bowl surface. We solved this problem by integrating an ionizer into a vibratory parts feeding system.

Read the Case Study >> Vibratory Feeder Bowl Reliably Feeds O-Rings

Hybrid Vibratory Feeder – Conveyor System for Gentle Parts Handling

A component of a sensor for a consumer product was made of a plastic material that was susceptible to damage from vibration. The assembly operation also required that the parts be kept as clean as possible. We designed a custom parts feeding system that combined a vibratory feeder bowl and straight line track with belt conveyors to provide an effective solution to these unique design challenges.

Read the Case Study >> Hybrid Vibratory Feeder – Conveyor System for Gentle Parts Handling

Ultra-Compact Vibratory Bowl Feeder Orients Small Rubber Parts

This vibratory bowl feeder was designed to feed an automotive part. With a low feed rate and tight space requirements, we designed a parts feeding system that allowed our customer to pick the part up directly from the bowl.

Read the Case Study >> Ultra-Compact Vibratory Bowl Feeder Orients Small Rubber Parts

Vibratory Feeder Bowl System with Center Discharge

This vibratory parts feeding system was designed to feed two sizes of a part used in air conditioner desiccant systems. The simple cylindrical shape of the parts allowed the use of a “cascade” type bowl feeder, where all part orientation is performed within the inside diameter of the bowl. This eliminated tooling construction on the outside of the bowl, which along with the right-angle discharge into the vibratory track, resulted in a compact vibratory feed system that met our customer’s space requirements.

Read the Case Study >> Vibratory Feeder Bowl System with Center Discharge

Vibratory Feeder Bowl Feeds Parts with Two Orientations

The assembly operation required two parts being placed simultaneously with the bushing flanges facing away from each other, as shown here. This would normally require two part feeding systems: One feeding the part with the flange up, and another feeding the part with the flange down. We saved our customer the expense and space consumption of a second feed system by designing a single vibratory parts feeder bowl that discharged two lines of parts with one line on top of the other.

Read the Case Study >> Vibratory Feeder Bowl Feeds Parts with Two Orientations