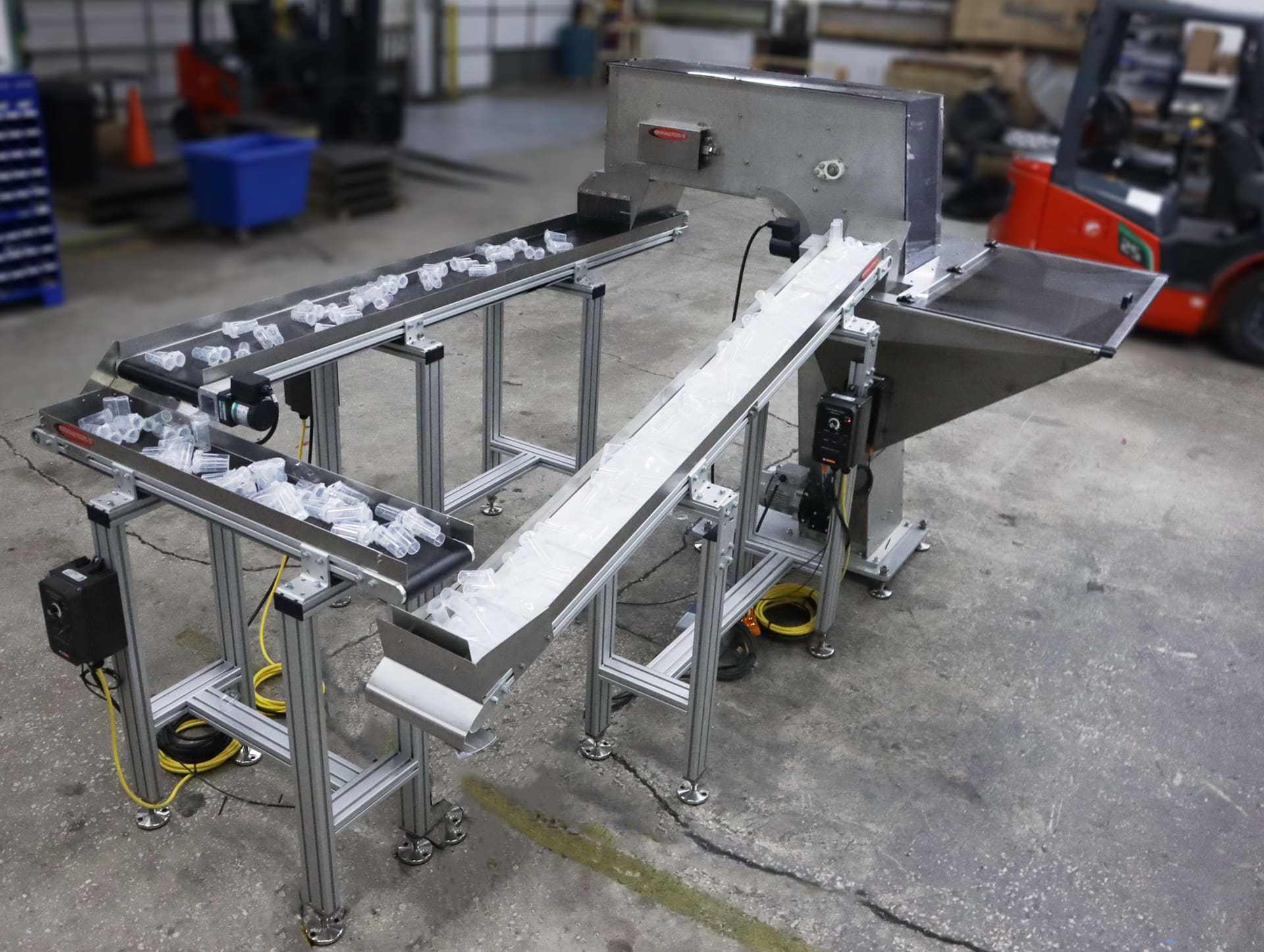

This Flexible Feeding solution was designed to feed double and singly wrapped medical vials for robotic selection at 100PPM. This system includes both belted and cleated conveyors, bin sensors to detect low parts supply, stack light alerts, and a robotic inspection system.

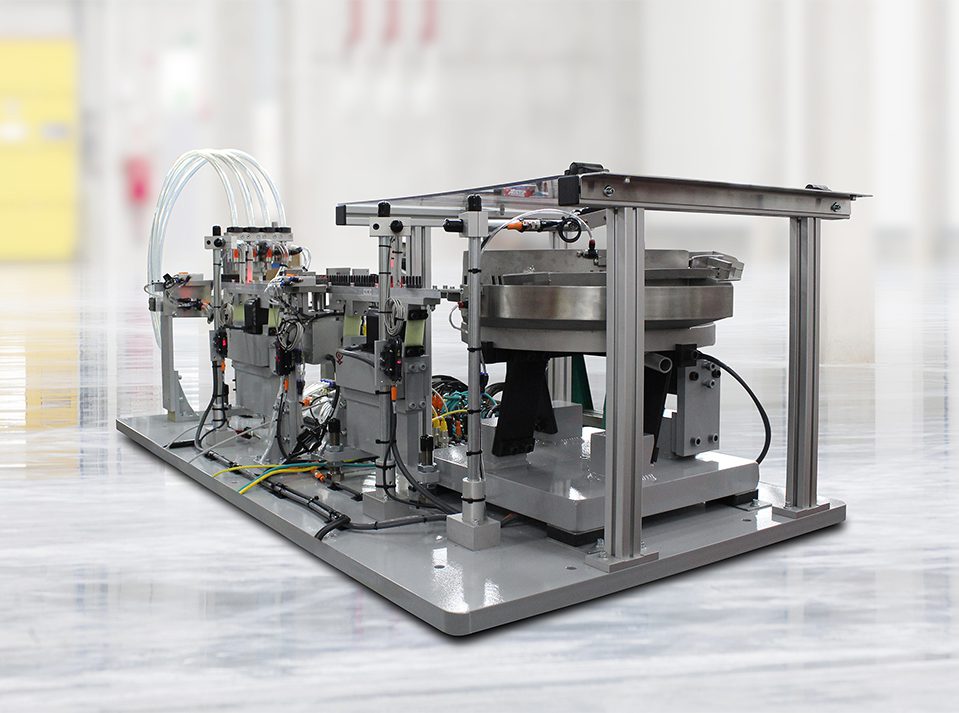

Vibratory Feeder System with Camera Vision Monitors Parts Orientation

The versatile outside-tooled vibratory feeder bowl is the foundation of this part feeding solution designed to orient bolt blanks for our customer, a manufacturer of fastening products. The vision system verifies that each bolt blank is in the required position. A C-track mounted at the end of the conveyor delivers the parts to the customer’s downstream operation at 40 parts per minute.

Vibratory Feeder with Rotary Inspection

This vibratory feed system includes a laser inspection station, a bowl level sensor, a track sensor, and a sorting indexer. Parts with an incorrect length are rejected while the correct parts are oriented threads-up in groups of 4.

Vibratory Feeder With Integrated Optical Inspection System Orients Parts Based On Internal Features

This vibratory feed system was designed to feed a metal washer into a machine assembling a consumer product. While flat, round parts like washers are normally easy to feed, this part had a small indentation on one side that needed to be oriented facing down. A Vision System checked the part for correct orientation before discharging it onto a straight-line track and into the customer’s assembly station.

Vibratory Bowl Feeder with Optical Inspection System

This application required feeding 3 different lengths of a small steel shaft into a centerless grinding machine. Parts were oriented in the vibratory bowl and monitored for 100% accuracy by a vision system. Parts were discharged onto an Auto-Kinetics belt conveyor which moved the parts into our customer’s centerless grinding machine.