High Speed Centrifugal Feed System for Medical Product

Jump to: System Specifications || Quote Request Form

Featuring a vertical elevating prefeeder and high speed gravity roller tracks, this centrifugal feed system was developed to feed and orient medical product in excess of 800 ppm and built to run 24/7 in a continuous production environment, while using the smallest footprint possible and preserving the integrity of the parts being fed.

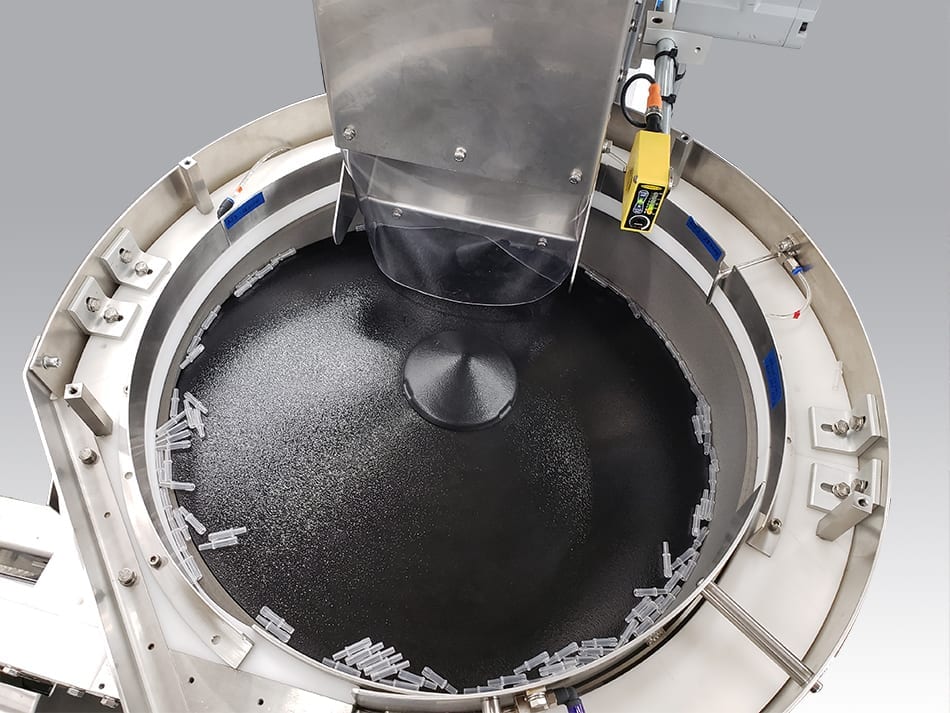

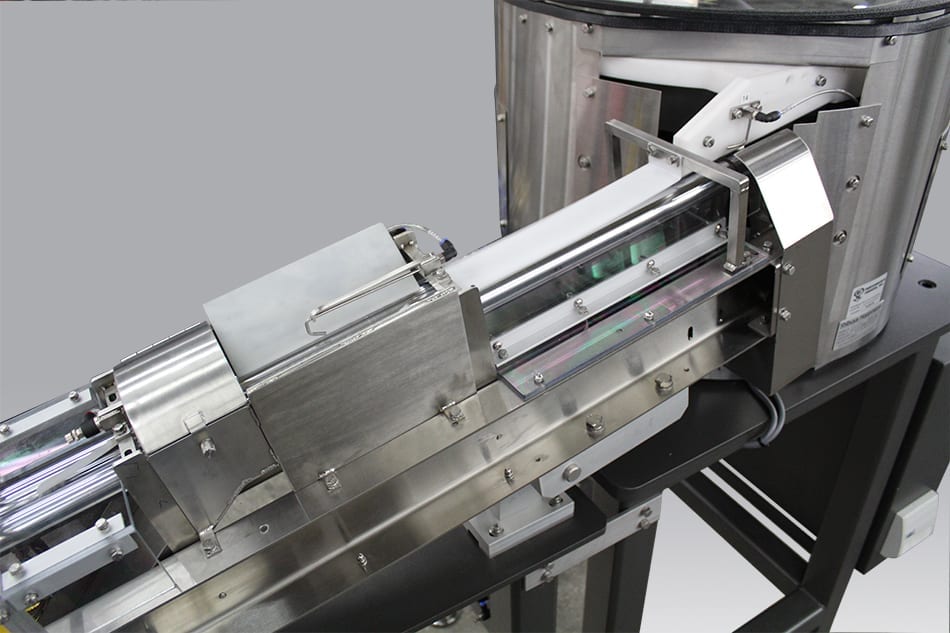

This short video demonstrates a vertical elevating prefeeder and high speed gravity roller tracks, this centrifugal feed system was developed to feed and orient medical product in excess of 800 ppm and built to run 24/7 in a continuous production environment, while using the smallest footprint possible and preserving the integrity of the parts being fed. The vertical elevating prefeeder allowed an operator to load product at an ergonomic level and metered the product into a centrifugal feeder, which separated and singulated the product into a random front to back pre-orientation and discharged them into precision orienting gage rollers which performed the final orientation of the product and carried it to the customer’s downstream application.

System specifications

- Feed rate: 800+ parts per minute

- Input voltage: 220V / 60 Hz.

- Centrifugal Bowl:

- 20″ Bowl diameter

- Clockwise rotation

- Stainless steel exterior construction

- Teflon hardcoat anodized aluminum bowl

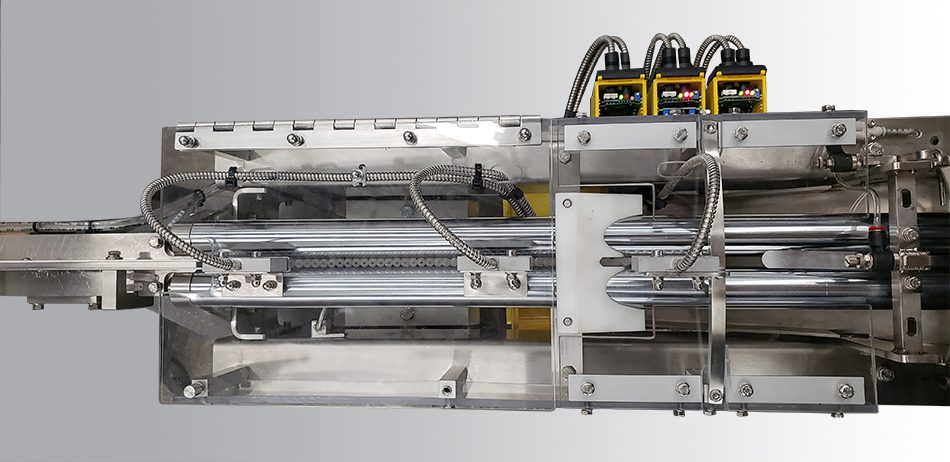

- High Speed Gravity Rollers:

- Adjustable delivery angle

- Geared motor

- Polished chrome precision roller shafts

- Roller 1.25″ DIA, 48″ long

- Mounting surface: 1″ thick steel table top with 5 legs and leveling pads

- Sensors:

- Glass fiber sensor array

- Bowl level sensors