This system was designed to feed a low voltage light bulb into an automotive assembly operation. A step feeder was chosen due because its gentle part handling characteristics would minimize the chance of breaking the parts.

Application Spotlight: Vibratory Bowl Feeds 300 Parts Per Minute

Application Spotlight: Vibratory Bowl Feeds 300 Parts Per Minute Our latest case study shows that vibratory bowl feeders are capable of producing high feed rates. This vibratory feed system fed 10 lines of a medical/pharmaceutical product for a total output of over 300 parts per minute. Read the full article here.

10-Line Vibratory Feeder System for Medical Manufacturing

This vibratory feeder was designed to feed three different styles of cylindrical plastic parts being assembled into a medical product. The parts were all the same diameter with slightly different heights. Four lines of parts ran out of the bowls then were merged into two lines feeding a vibratory track.

Application Spotlight: Vision System Aids Orientation in Vibratory Bowl Feeder

Application Spotlight: Vision System Aids Orientation in Vibratory Bowl Feeder Our latest case study, which is featured in the May issue of Assembly Magazine, illustrates how we integrate vision systems with vibratory feeders when part orientation can’t be achieved mechanically. Read the full article here.

Application Spotlight: Step Feeder System For Automotive Product

Application Spotlight: Step Feeder System For Automotive Product Our latest case study details how we utilized our electric drive step feeder to feed magnets being assembled into an automotive product. Read the full article here.

Vibratory Bowl Feeder with Optical Inspection System

This application required feeding 3 different lengths of a small steel shaft into a centerless grinding machine. Parts were oriented in the vibratory bowl and monitored for 100% accuracy by a vision system. Parts were discharged onto an Auto-Kinetics belt conveyor which moved the parts into our customer’s centerless grinding machine.

Step Feeder Orients Differently-Sized Automotive Parts

This system was designed to feed 2 sizes of magnets being assembled into an automotive product. A step feeder was chosen for space savings and durability. This system features a step feeder bin, proximity sensors, and a pre-feeder conveyor belt.

Visit us at ATX South

We are pleased to offer you free admission to the ATX South expo (a $75 value) in Charlotte NC on April 15-16, 2014. Attending ATX South gives you direct access to the industry’s leading suppliers, the latest products and technologies, networking opportunities, educational Learning Labs, and much more. Visit us at booth #1633 where we […]

Centrifugal feeders for high feed rate applications

Centrifugal feeders for high feed rate applications Centrifugal feeders are capable of very high feed rates. Our latest case study shows a centrifugal feeder we recently built that fed pharmaceutical parts at 1300 parts per minute. Read the full article here.

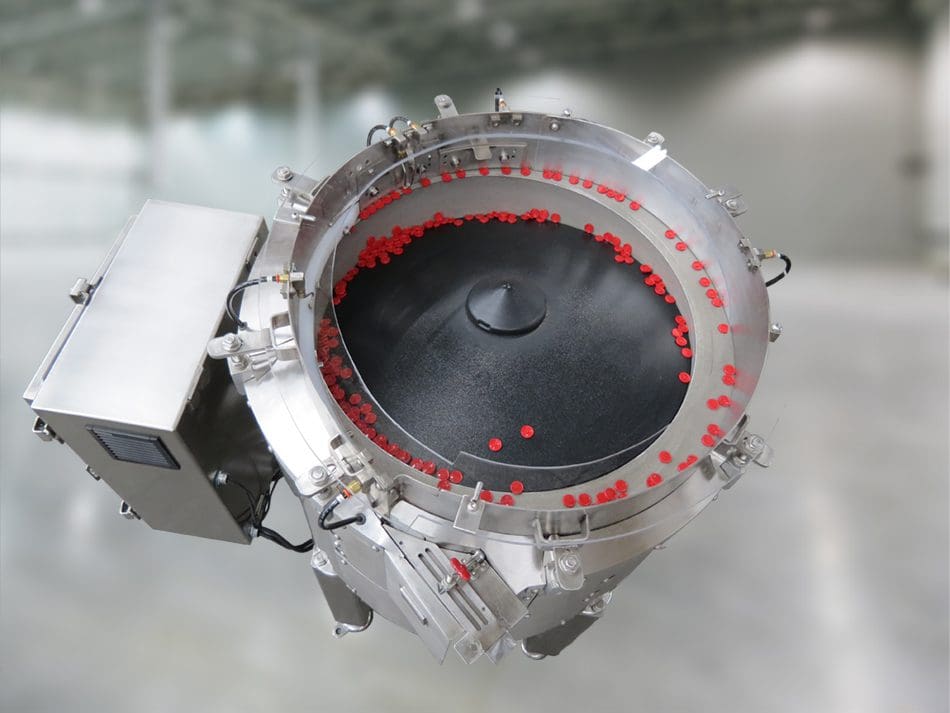

Centrifugal Feeder Feeds 1300 Pharmaceutical Parts per Minute

This system was designed for a pharmaceutical product manufacturer who needed to orient and feed two types of round plastic parts at a rate of 1300 parts per minute. We used a centrifugal bowl feeder for this project because of the high feed rate requirement.