Performance Feeders participated in the Tampa Bay Packaging Open House to provide tours of our manufacturing facility in Oldsmar, FL this past week. Over 25 attendees visited Performance Feeders. Our team interacted with multiple vendors and local and national packaging company representatives toward building a continued network of manufacturing relationships. It has been a valuable […]

Tampa Bay Packaging Manufacturers Open House

Join us February 26th – March 1, 2024 for the Tampa Bay Packaging Open House, Golf Tournament, and Reception. Please stop by Performance Feeders to tour our facility, meet our team, and check out the latest innovations in packaging technology.

Performance Feeders Supports Workforce Training Program

Performance Feeders donated a Vari-Flex Feeder, a programmable state-of-the-art system that uses a recirculating turntable to present parts for vision and robotic selection, to St. Petersburg College’s (EMBA) department, a provider of skilled workforce training. PMMI generously matched our donation!

PFVF-03 Vari-Flex Feeder Nominated for New Product of the Year Award by The Assembly Show!

For the 2nd year, The Assembly Show has nominated 20 products in five categories that are particularly innovative and represent the best new products of 2019. Performance Feeders is proud to announce that our PFVF-03 Vari-Flex Feeder is one of four nominees in the Assembly Machines & Systems category! Stop by Booth #1417 and find […]

Trends in Pharmaceuticals and Medical Device Manufacturing

Trends in Pharmaceuticals and Medical Device Manufacturing While they are in different industries, pharmaceutical and medical device companies often face a surprisingly similar array of challenges and market realities. Companies in both industries are actively addressing new government regulations often resulting in new equipment purchases. Simultaneously, both industries are under increasing pressure to produce more […]

What is ‘Industry 4.0’?

What is ‘Industry 4.0’? Industry 4.0 or “i4.0” is the next wave of manufacturing, often referred to as ‘smart factories’. i4.0 includes automation and data exchange in manufacturing processes, cyber-physical systems, the Internet of Things (IoT), and cloud computing. According to a recent KPMG report on i4.0 “Gartner believes that the Internet of Things (IoT) […]

Rising Demand for Vision-Aided Feeding

Rising Demand for Vision-Aided Feeding Photoelectric sensors are used to detect the size, shape, color, distance, orientation or absence/presence of a the part moving through the assembly process. These sensors use a light transmitter to provide a signal to the sensor receiver which is programmed to take an action based on the result. Sensors are […]

Vision Systems in Food Production Automation

Vision Systems in Food Production Automation Interesting article on the use of vision systems in food production. “Industrial robots can quickly and easily pick and place food items without risk of introducing bacteria and at a rate far faster and with greater endurance than a human worker. Advanced vision systems even have the capacity to […]

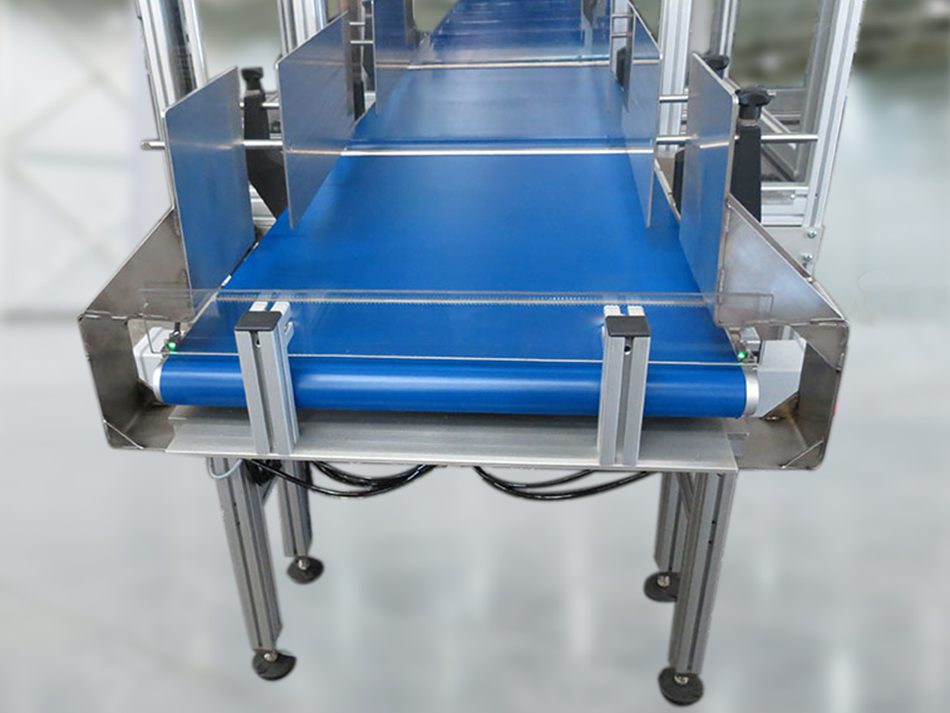

Belt Conveyors: The Workhorse of Automation

Belt Conveyors: The Workhorse of Automation Belt conveyor systems play an important role by minimizing the production cycle time in automated processes. The conveyor systems market is undergoing radical change due to factors such as industrial expansion, modernization and technological advancement. Belt and roller conveyor systems continue to generate significant demand but with requirements for […]

Big Changes Afoot In Food Packaging Automation

Big Changes Afoot In Food Packaging Automation There are significant changes coming to the way consumers purchase and consume food over the next 15 years – and packaging automation will have to change rapidly to meet these new demands. Changes in consumer preferences include: Food trends show continued growth towards convenience and healthy choices with […]