Belt Conveyors: The Workhorse of Automation

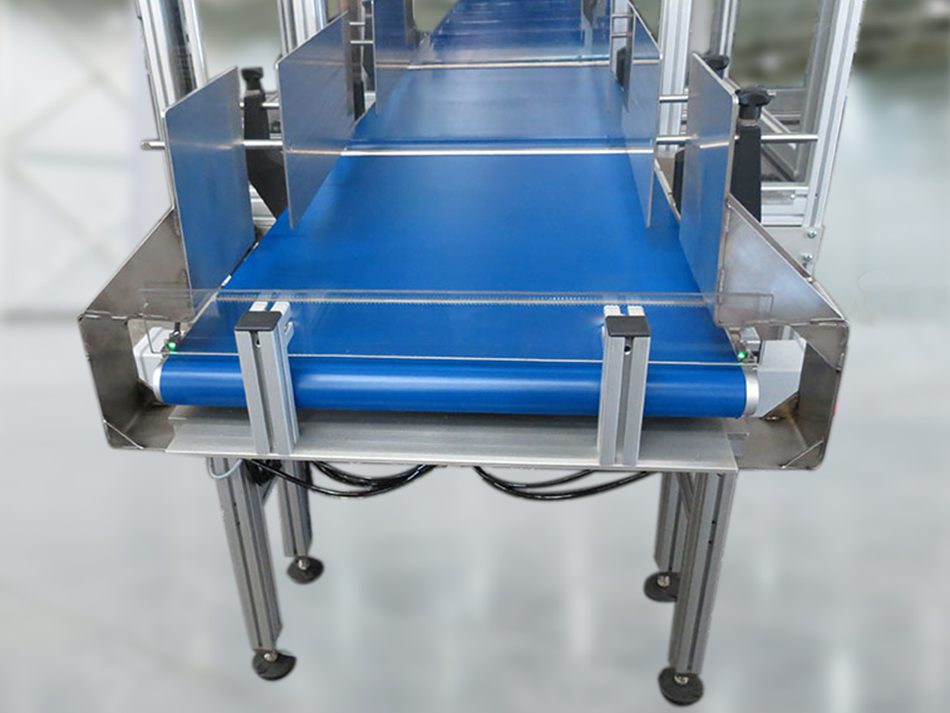

Belt conveyor systems play an important role by minimizing the production cycle time in automated processes. The conveyor systems market is undergoing radical change due to factors such as industrial expansion, modernization and technological advancement. Belt and roller conveyor systems continue to generate significant demand but with requirements for ever-higher efficiency, we are seeing more requests for customized conveyor systems that increase efficiencies and lower production costs.

In addition to the more traditional uses of conveyor belt systems in food production and packaging, pharmaceutical packaging, parts manufacturing and other assembly line operations, we are seeing new uses for belt conveyor system ranging from food delivery systems at trendy Chicago (and Japanese!) restaurants to automation of TSA security lines for better safety. Conveyor belt systems are finding new uses as 3D printing increasingly comes into play, acting as the link between the printers and the human beings who collect the finished product from a conveyor-powered delivery system.

Whether you are in a “traditional” parts handling or production business or branching out into new segments of the market, conveyor systems are truly the workhorse that lower production costs and increase efficiences. Performance Feeders has considerable expertise in the custom belt conveyor market, building integrated systems for a wide variety of industries and uses. Our new Conveyor Configurator tool simplifies the process of designing a custom conveyor system that integrates seamlessly to your existing production line. We have a number of 2D and 3D solid models available for download and of course, our engineers are always available to help you with the design of your system. Request a quote online or contact us today to get started on your next integrated conveyor system project!