Manufacturing Capabilities

Jump to: Advanced Process || 5-Axis CNC || ProtoTrak Machined Tooling

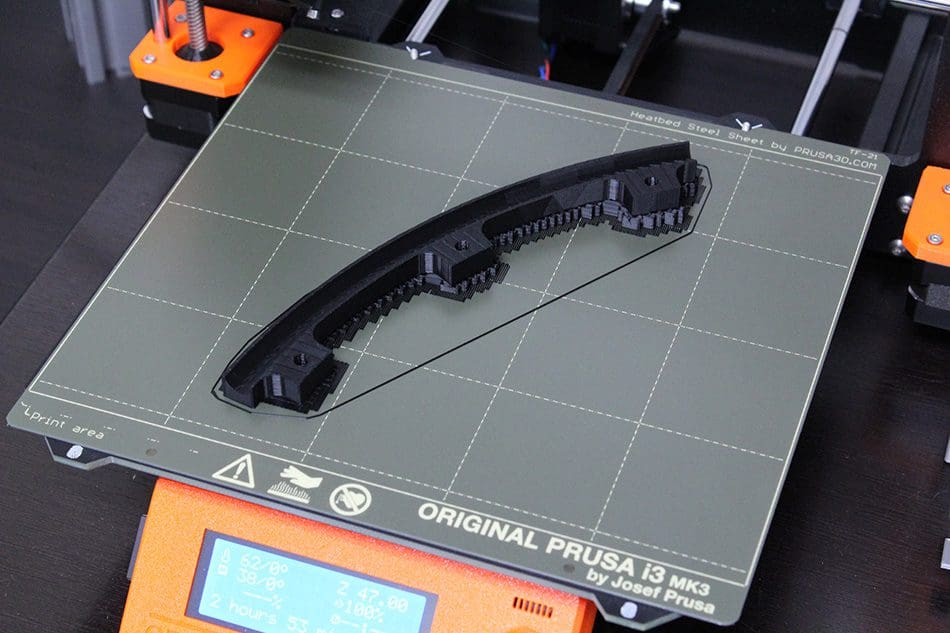

Engineered Tooling with 3-D Printer

The tooling of vibratory feeders traditionally involves manual fabrication, a process that presents challenges when an application requires a duplicate feed system, or a product enhancement requires a change of tooling for the part orientation process.

Our 3-D printer allows us to create engineered prototypes of bowl feeder tooling that are more easily duplicated with newer machining technologies. These printed prototypes offer improved accuracy during the system debug process.