This vibratory bowl feeder was designed to feed an automotive part. With a low feed rate and tight space requirements, we designed a parts feeding system that allowed our customer to pick the part up directly from the bowl.

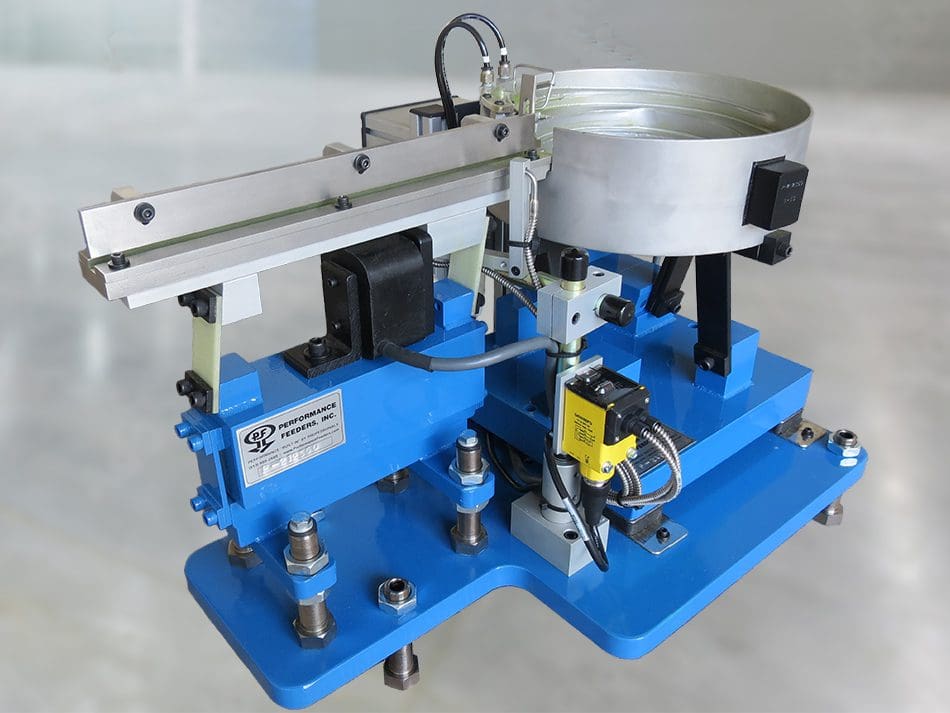

Vibratory Feeder Bowl System with Center Discharge

This vibratory parts feeding system was designed to feed two sizes of a part used in air conditioner desiccant systems. The simple cylindrical shape of the parts allowed the use of a “cascade” type bowl feeder, where all part orientation is performed within the inside diameter of the bowl. This eliminated tooling construction on the outside of the bowl, which along with the right-angle discharge into the vibratory track, resulted in a compact vibratory feed system that met our customer’s space requirements.

Vibratory Feeder Bowl Feeds Parts with Two Orientations

The assembly operation required two parts being placed simultaneously with the bushing flanges facing away from each other, as shown here. This would normally require two part feeding systems: One feeding the part with the flange up, and another feeding the part with the flange down. We saved our customer the expense and space consumption of a second feed system by designing a single vibratory parts feeder bowl that discharged two lines of parts with one line on top of the other.

High-Precision, FDA Approved Cleated Timing Belt Conveyor System

This custom conveyor system was designed to transfer blister packs of medical products between machinery assembling the blister packs and machinery packaging the packs into cartons. Packs were loaded onto the conveyor at the entrance end and shuttled sideways into a packaging machine at the discharge end. The high-precision requirements of this application necessitated the use of a custom timing belt conveyor.

Conveyor Belt System with Automatic Tray Loading

This Custom Conveyor System was designed for a manufacturer who needed to load empty trays with parts for an automatic assembly operation. Empty trays were loaded onto a powered Auto-Kinetics heavy-duty belt conveyor. Upon reaching the end of the belt conveyor, a pneumatic slide pushed a single tray sideways onto a robotic loading station. Once in position, a second pneumatic slide clamped the tray in place for loading.